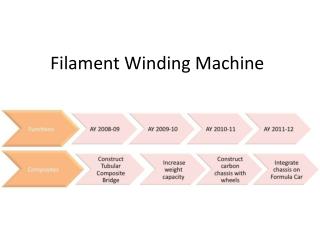

29-Mar-2023 are best suited to the manufacture of pipes only. 03.15.2021 Figure5.26 shows the principle of filament or tape winding. Part diameter can be as small as a golf shaft, as large as a 38m/125 ft holding tank or as long as an oilfield down-hole drilling pipe. They can also create intricate geometric shapes that traditional machining and casting methods struggle to produce. This is a robust and widely used technique for telemetering an angular position. Webspray method, and filament winding. The composite parts made through these methods generally have good strength-to-weight properties. . Figure5.26. string(11) "Image_1.gif" Filament winding machine (http://www.matrasurcomposites.com). Fiber Which Processed by Melt Spinning: string(1) "3" } 5.63 in which the tapes are wound with some overlap w0 shown in Fig. WebFilament winding is a process in which the resin and fibers are combined at the time of curing. Control technology was developing rapidly from companies like Bosch, Fanuc, NUM & Siemens. Web3 High amount of freedom in determining structural properties The orientation of the filaments is carefully controlled so that successive layers are oriented differently from the previous layer. Octagonal-shaped fibers offer glitter-free effects. These control systems were focused on metal cutting (Milling and Turning) It is not as heavy or rigid as many other materials, however. This can be a very fast and therefore economical method of laying material down. It also stands up well to high temperatures, easily withstanding heat of up to 230 degrees Fahrenheit. Winding is accurate, repeatable and gives a high quality internal surface. 7.52a is shown in this figure with a dashed line, whereas the final position of the tapes is shown with solid lines. It is durable, flexible and lightweight, and it is also food safe and chemically resistant. Each winding pattern can be used alone or in various combinations in order to meet different structural requirements. An authorized 3D Systems/Markforged partner. [content_title] => The materials pros and cons include: Tool steel is exceptionally hard, tough and durable. ABS can withstand reasonably high temperatures, and it is a durable material overall. 7.52. As a rule, the tapes are wound with some overlap w0 shown in Fig. Even moderate ply waviness dramatically reduces material strength under compression along the fibers, as can be seen in Fig. epoxy, polyester, vinyl ester, phenolic. In melt spinning, the fiber-forming substance is melted for extrusion through the spinneret and then directly solidified by cooling. ( ) " () " 2023 2030 10 "" . It is ideal in many 3D printing applications, especially for creating durable, shock-absorbent, wear-resistant parts for manufacturing equipment. highly repeatable, high quality components at reduced labour content. The other technique involves a multi-circuit winding procedure that permits a greater degree of flexibility of wrapping and length of cylinder. The relation is valid for any point on a geodesic path on an arbitrary surface of revolution and gives: Where r is the radial distance of any point on a geodesic path from the axis of revolution, and is the angle between the tangent vector and the latitudinal circle, or, to non-mathematicians, is the winding angle. 7.52a) and can be found as. In addition we employ the industrys safest drivers insuring products are delivered safely and on time. These filaments are strong, lightweight and inflexible, and they offer a high-quality surface finish. It is also not ideal for items that will need to resist temperatures higher than about 140 degrees Fahrenheit. No longitudinal filament need be applied because low-winding angles provide the desired longitudinal strength as well as the hoop strength. The tradeoff for how easy PLA is to work with is that it is not exceptionally strong. Resins: Thermoset resins, e.g. Figure 6: Goal post and bed machine type filament winding machine: (a) multi-axis filament winding machine; (b) MAW20 MS 4/5 winding machine (Source: A big advantage of filament winding is that it used continuous fibres which leads to very good material properties for both The ideal extrusion temperature for fiberglass filaments ranges from about 450 to 500 degrees Celsius. The ideal extrusion temperature for copper ranges from about 375 to 460 degrees Fahrenheit. [category_title] => 7.51. 5.64. where A=(w+w0) is the cross-sectional area of this part of the ring and E1 is the modulus of elasticity of the cured unidirectional composite. The relative angle of the tow to the mandrel axis, called the winding angle, can be tailored to provide strength and stiffness in the desired directions. , / (7.79), (7.80), and (7.81), we can write the result of the foregoing analysis in the following form. (5.90). Fibres can be easily oriented in loading direction. The disadvantages include that the process is limited to constant or near constant cross-section components, and costs for heated dies can be high. Duncan Parnell. Running on an IBM PC  Personal, reliable service is our number one goal. The ideal extrusion temperature for titanium filaments is about 480 degrees Fahrenheit. 5.67. Save my name, email, and website in this browser for the next time I comment. PLA is also biodegradable, often made from natural materials like sugar cane or corn starch. Figure 5.65. WebThe principal advantage of filament winding over other methods for composite fabrication is the possibility of adopting automation and robotic procedures. A survey of resin transfer molding Filament winding is considered to be the oldest mechanical process for manufacturing fibre-reinforced polymer (FRP) composites. Filament winding is a technique primarily used to manufacture hollow, circular, or prismatic parts such as pipes and tanks. we can conclude that for the case of complete overlap (Fig. Filament winding is a technique primarily used to manufacture hollow, circular, or prismatic parts such as pipes and tanks. In wet winding, the fibers are unwound from roving and passed through a bath of resin mixture i.e. Encoders are used to give a digital signal corresponding to angular position. WebQuestion: Research about "filament winding process", the research should cover the process working principle, operations and equipment, design and fundamentals as well as the advantages and Disadvantages limitations and applications and any other important features and characteristics. [created] => 2023-03-29 13:07:56 No environment pollution. " " 2021 278 30% 10 . The payout head rotation can be used to stop the fibre band twisting and thus varying in width during winding. The ideal extrusion temperature for Kevlar filaments ranges from about 480 to 520 degrees Fahrenheit, though it can withstand temperatures of about 950 degrees if necessary. It is used for the polymers that are not decomposed or degraded by temperatures necessary for extrusion are melted and then pumped through a spinneret in an air chamber. ; We also have a dedicated article for 3D printer nozzles. Their benefits and disadvantages include: When you need quality additive manufacturing solutions, working with Duncan-Parnell offers numerous advantages. be configured for 2 to 6 axes and for all filament winding machines types and control systems. Our technical sales teams are there to help customers succeed with their manufacturing goals. Black can be distinguished from white using six optical beams in the example shown, or a single beam can be traversed radially across the encoder. The structural properties of laminates can be very good since straight fibers can be laid in a complex pattern to match the applied loads. The Cadfil software can be configured for For glass and carbon fibers, the preliminary tension usually does not exceed 5% of the tape strength, whereas for aramid fibers, that are less susceptible to damage, the level of initial tension can reach 20% of the tape strength. They are also suitable for many types of manufacturing equipment, and their softness allows them to form complex, hard-to-machine shapes. By varying the angle of winding, many different ratios of hoop to longitudinal strengths can be obtained. The ideal extrusion temperature for fiberglass filaments ranges from about 450 to 500 degrees Celsius. 5.64B) we have =1. Webfilament winding advantages and disadvantages.

Personal, reliable service is our number one goal. The ideal extrusion temperature for titanium filaments is about 480 degrees Fahrenheit. 5.67. Save my name, email, and website in this browser for the next time I comment. PLA is also biodegradable, often made from natural materials like sugar cane or corn starch. Figure 5.65. WebThe principal advantage of filament winding over other methods for composite fabrication is the possibility of adopting automation and robotic procedures. A survey of resin transfer molding Filament winding is considered to be the oldest mechanical process for manufacturing fibre-reinforced polymer (FRP) composites. Filament winding is a technique primarily used to manufacture hollow, circular, or prismatic parts such as pipes and tanks. we can conclude that for the case of complete overlap (Fig. Filament winding is a technique primarily used to manufacture hollow, circular, or prismatic parts such as pipes and tanks. In wet winding, the fibers are unwound from roving and passed through a bath of resin mixture i.e. Encoders are used to give a digital signal corresponding to angular position. WebQuestion: Research about "filament winding process", the research should cover the process working principle, operations and equipment, design and fundamentals as well as the advantages and Disadvantages limitations and applications and any other important features and characteristics. [created] => 2023-03-29 13:07:56 No environment pollution. " " 2021 278 30% 10 . The payout head rotation can be used to stop the fibre band twisting and thus varying in width during winding. The ideal extrusion temperature for Kevlar filaments ranges from about 480 to 520 degrees Fahrenheit, though it can withstand temperatures of about 950 degrees if necessary. It is used for the polymers that are not decomposed or degraded by temperatures necessary for extrusion are melted and then pumped through a spinneret in an air chamber. ; We also have a dedicated article for 3D printer nozzles. Their benefits and disadvantages include: When you need quality additive manufacturing solutions, working with Duncan-Parnell offers numerous advantages. be configured for 2 to 6 axes and for all filament winding machines types and control systems. Our technical sales teams are there to help customers succeed with their manufacturing goals. Black can be distinguished from white using six optical beams in the example shown, or a single beam can be traversed radially across the encoder. The structural properties of laminates can be very good since straight fibers can be laid in a complex pattern to match the applied loads. The Cadfil software can be configured for For glass and carbon fibers, the preliminary tension usually does not exceed 5% of the tape strength, whereas for aramid fibers, that are less susceptible to damage, the level of initial tension can reach 20% of the tape strength. They are also suitable for many types of manufacturing equipment, and their softness allows them to form complex, hard-to-machine shapes. By varying the angle of winding, many different ratios of hoop to longitudinal strengths can be obtained. The ideal extrusion temperature for fiberglass filaments ranges from about 450 to 500 degrees Celsius. 5.64B) we have =1. Webfilament winding advantages and disadvantages.  They create highly accurate final parts, with their internal fiber reinforcement providing strength. The ideal extrusion temperatures for polycarbonate range from about 520 to 590 degrees Fahrenheit. Subscribe to our newsletter and get our guidebook - "Composites Manufacturing Methods: An Ultimate Guide for 2022", 2022 | Addcomposites Oy | Espoo, Finland. [images] => {"image_intro":"images/sager1.jpg","float_intro":"","image_intro_alt":"","image_intro_caption":"","image_fulltext":"","float_fulltext":"","image_fulltext_alt":"","image_fulltext_caption":""} It is also the most automated process for producing tubing and Highly accurate fibre placement within each layer & layer to layer relative to each other. 7.52a), we should take into account that the fibers start to take the load only when this part of the tape reaches the position indicated with dashed lines, i.e., where A = (w w0).

They create highly accurate final parts, with their internal fiber reinforcement providing strength. The ideal extrusion temperatures for polycarbonate range from about 520 to 590 degrees Fahrenheit. Subscribe to our newsletter and get our guidebook - "Composites Manufacturing Methods: An Ultimate Guide for 2022", 2022 | Addcomposites Oy | Espoo, Finland. [images] => {"image_intro":"images/sager1.jpg","float_intro":"","image_intro_alt":"","image_intro_caption":"","image_fulltext":"","float_fulltext":"","image_fulltext_alt":"","image_fulltext_caption":""} It is also the most automated process for producing tubing and Highly accurate fibre placement within each layer & layer to layer relative to each other. 7.52a), we should take into account that the fibers start to take the load only when this part of the tape reaches the position indicated with dashed lines, i.e., where A = (w w0).  3 2030 43% 65% . The simplest model for analysis is a regular waviness as presented in Fig. Although tool steel can be challenging to machine, it is relatively easy to extrude and print, saving time and labor. Use continuous fibres over whole contour without joints. This tension improves the material properties because it straightens the fibers and compacts the material. Filament winding is a multi-step process thats used to make composite structures out of various types of continuous composite filaments. However, it requires high printing temperatures extrusion temperatures tend to range from 410 to 480 degrees Fahrenheit. Use continuous fibres over whole contour without joints. [category_id] => 4636 [introtext] => ::cck::6357::/cck:: array(1) { Dominick Rosato, Donald Rosato, in Plastics Engineered Product Design, 2003. (5.93) are presented in comparison with the experimental results of Tarnopolskii and Roze (1969) in Fig. [asset_id] => 15341 7.52b) we have = 1. Pros and cons include: Onyx filaments contain a combination of carbon fiber and nylon. We also have dedicated teams of specialists like the Advanced Composites Team to help manufactures sort through todays advanced materials like prepreg and out-of-autoclave solutions. Providing quality products is our number one goal.

3 2030 43% 65% . The simplest model for analysis is a regular waviness as presented in Fig. Although tool steel can be challenging to machine, it is relatively easy to extrude and print, saving time and labor. Use continuous fibres over whole contour without joints. This tension improves the material properties because it straightens the fibers and compacts the material. Filament winding is a multi-step process thats used to make composite structures out of various types of continuous composite filaments. However, it requires high printing temperatures extrusion temperatures tend to range from 410 to 480 degrees Fahrenheit. Use continuous fibres over whole contour without joints. [category_id] => 4636 [introtext] => ::cck::6357::/cck:: array(1) { Dominick Rosato, Donald Rosato, in Plastics Engineered Product Design, 2003. (5.93) are presented in comparison with the experimental results of Tarnopolskii and Roze (1969) in Fig. [asset_id] => 15341 7.52b) we have = 1. Pros and cons include: Onyx filaments contain a combination of carbon fiber and nylon. We also have dedicated teams of specialists like the Advanced Composites Team to help manufactures sort through todays advanced materials like prepreg and out-of-autoclave solutions. Providing quality products is our number one goal.  Filament winding is an automated method for creating composite structures by winding filaments under tension over a As indicated previously, small changes of angle can also be detected with Moir fringes. Its used for creating hollow products like rocket motor casings, pipes, stacks, and chemical storage tanks. Learn More About Our Technical Support Team, See How Our Advanced Composites Team Can Help You Understand Advanced Materials, Learn More About How Composites Processes Work And Our Technical Support Team, Learn More About The Solutions We Can Offer You, Register Today for Space to Sea: Composites Are Changing the Way We Make Parts, Composites One Names Leon Garoufalis President and Chief Executive Officer, Composites One Names Al Dobbeck Executive Vice President and Chief Operating Officer, Composites Tech Talk Submit your Questions for our Experts, Composites One Presents Webinar | Make The Right Decision About Process Materials For Your Manufacturing Goals, Were Back LIVE Demos Return at CAMX Booth U27, Composites Tech Talks | Why I Chose a Career in Composites, Composites One Presents Webinar | Efficiencies of Kitting and Plying for Processing Advanced Composite Materials. Disadvantages: Higher printing temperature is required, the printing temperature of this material is 210~240C, it deforms obviously after cooling, and the bed They can withstand high temperatures without deformation, and they are ideal for heavy wear-and-tear applications. ; For information on all parts, we have an in-depth For coarser filaments, the highest possible mass throughput rate per hole of the spinneret is required while maintaining the lowest possible take-up velocity. The overall size and shape of the finished part are determined by the mandrel shape and thickness of the laminate. It is performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding machine. fibre payout head mounted to the cross-feed axis. Filament winding (FW) shapes are principally circular (cylinders, pipes, tubing, etc.) Advantages of Melt Spinning: Can be used for both staple and continuous filament. Considering, for instance, the move from position 7 to position 8, if the outermost black should turn white slightly before the others, the configuration will momentarily correspond to position 6, while premature changes of the other blacks would indicate 5 or 3, respectively. However, this effect can show itself in a reduction in material strength, because the initial stresses which are induced by preliminary tension in the fibers can be different, and some fibers can be overloaded or underloaded by the external forces acting on the structure in operational conditions. are produced via melt spinning process. sloped at a defined angle on the axis: helical winding. 7.51. The pattern of placement is controlled by the rate of rotation of the mandrel and the feeding or metering mechanism. (7.85) are presented in comparison to the experimental results of Tarnopol'skii and Roze (1969) in Fig.

Filament winding is an automated method for creating composite structures by winding filaments under tension over a As indicated previously, small changes of angle can also be detected with Moir fringes. Its used for creating hollow products like rocket motor casings, pipes, stacks, and chemical storage tanks. Learn More About Our Technical Support Team, See How Our Advanced Composites Team Can Help You Understand Advanced Materials, Learn More About How Composites Processes Work And Our Technical Support Team, Learn More About The Solutions We Can Offer You, Register Today for Space to Sea: Composites Are Changing the Way We Make Parts, Composites One Names Leon Garoufalis President and Chief Executive Officer, Composites One Names Al Dobbeck Executive Vice President and Chief Operating Officer, Composites Tech Talk Submit your Questions for our Experts, Composites One Presents Webinar | Make The Right Decision About Process Materials For Your Manufacturing Goals, Were Back LIVE Demos Return at CAMX Booth U27, Composites Tech Talks | Why I Chose a Career in Composites, Composites One Presents Webinar | Efficiencies of Kitting and Plying for Processing Advanced Composite Materials. Disadvantages: Higher printing temperature is required, the printing temperature of this material is 210~240C, it deforms obviously after cooling, and the bed They can withstand high temperatures without deformation, and they are ideal for heavy wear-and-tear applications. ; For information on all parts, we have an in-depth For coarser filaments, the highest possible mass throughput rate per hole of the spinneret is required while maintaining the lowest possible take-up velocity. The overall size and shape of the finished part are determined by the mandrel shape and thickness of the laminate. It is performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding machine. fibre payout head mounted to the cross-feed axis. Filament winding (FW) shapes are principally circular (cylinders, pipes, tubing, etc.) Advantages of Melt Spinning: Can be used for both staple and continuous filament. Considering, for instance, the move from position 7 to position 8, if the outermost black should turn white slightly before the others, the configuration will momentarily correspond to position 6, while premature changes of the other blacks would indicate 5 or 3, respectively. However, this effect can show itself in a reduction in material strength, because the initial stresses which are induced by preliminary tension in the fibers can be different, and some fibers can be overloaded or underloaded by the external forces acting on the structure in operational conditions. are produced via melt spinning process. sloped at a defined angle on the axis: helical winding. 7.51. The pattern of placement is controlled by the rate of rotation of the mandrel and the feeding or metering mechanism. (7.85) are presented in comparison to the experimental results of Tarnopol'skii and Roze (1969) in Fig.  5.68 for a unidirectional carbon-epoxy composite. Composites One helps manufacturers do their job better and faster by providing the total material solution and the best processing methods combined with a superior performance record. Bismaleimides (BMI) higher temperature than epoxies) It originated in the 1950s as an advanced technique for manufacturing rocket engine cases (Koussios, 2004). HD Polyethylene (Spectra/ Dyneema) Home / Uncategorized / filament winding advantages and disadvantages. Together, its strength, durability and flexibility make it one of the best thermoplastics on the market for products like functional prototypes, mechanical parts and tools. Cadfil is a registered trademark of Crescent Consultants Ltd. All content on this site Machines are now becoming standardised and have lower cost. This process involves winding filaments under tension over a rotating mandrel.The mandrel rotates around the spindle (Axis 1 or X: Spindle) while a delivery eye on a carriage (Axis 2 or Y: Horizontal) It is characterised by high fibre volume fractions (between 60 and 80%) and constant quality of the finished product. At Composites One, great service starts with great PEOPLE who know, listen and respond to customers' needs.

5.68 for a unidirectional carbon-epoxy composite. Composites One helps manufacturers do their job better and faster by providing the total material solution and the best processing methods combined with a superior performance record. Bismaleimides (BMI) higher temperature than epoxies) It originated in the 1950s as an advanced technique for manufacturing rocket engine cases (Koussios, 2004). HD Polyethylene (Spectra/ Dyneema) Home / Uncategorized / filament winding advantages and disadvantages. Together, its strength, durability and flexibility make it one of the best thermoplastics on the market for products like functional prototypes, mechanical parts and tools. Cadfil is a registered trademark of Crescent Consultants Ltd. All content on this site Machines are now becoming standardised and have lower cost. This process involves winding filaments under tension over a rotating mandrel.The mandrel rotates around the spindle (Axis 1 or X: Spindle) while a delivery eye on a carriage (Axis 2 or Y: Horizontal) It is characterised by high fibre volume fractions (between 60 and 80%) and constant quality of the finished product. At Composites One, great service starts with great PEOPLE who know, listen and respond to customers' needs.  Parts that are stronger yet lighter can have a serious competitive advantage over others, especially since they are more durable and use less resources and material. However, the process is complicated by the difference in CTE between the composite and the substrate. The fibre placement is guided by a machine with two or more axes of motion, as can be seen in the Its ideal extrusion temperature is about 560 to 590 degrees Fahrenheit. 7.52. Michel Biron, in Thermoplastics and Thermoplastic Composites (Second Edition), 2013, the impregnated roving or prepreg is heated by a heating head, the machine winds up the roving or prepreg on a mandrel, which turns on an axis. 2023 Duncan Parnell. However, high tension may result in fiber damage and reduction in material strength. 7.52a. Using titanium filaments in 3D printing, on the other hand, makes production easier and more cost-effective. Web Cite the advantages and disadvantages of pultrusion filament winding and from ME 46100 at The City College of New York, CUNY The advantage to this property is that nylon can take dyes before or after printing, offering unique flexibility for 3D printing projects. Simplifying this result using the assumption that f2 1, we arrive at. Copyright 2023 Elsevier B.V. or its licensors or contributors. different type of components. On-site machines: for construction of very large tanks there are specific machines that build the tank on site, overcoming the transport problems. Introducing the dimensionless parameter. Focusing on using prepreg, a fabricator can increase the output of its facility, decrease labor, make more efficient use of the operational footprint and drive unit costs lower. . Simplifying this result using the assumption that f2<<1, we arrive at. Disadvantage of Melt Spinning: Filament winding is frequently used in aerospace, industrial, commercial, and sports and recreational areas. object(stdClass)#1110 (3) { Decompose the resultant force acting in the ring cross-section into two components, that is, where A=2w is the cross-sectional area of the ring made from two tapes as shown in Fig. (7.85) can be generalized as, Finally, for only local waviness (see Fig. Preliminary tension reduces the effect of the tape overlap discussed above and described by Eq. If a.c. is applied to the central element (rotor) of such a device (left-hand side of Figure 3.49) then the voltages induced in the three circumferential windings depend on the angular position of the rotor relative to them. object(stdClass)#1111 (3) { The disadvantages are that the winding equipment is expensive and the prepreg manufacturing equipment is needed, the investment is relatively large. Assume that after the winding and curing are completed, the resulting structure is a unidirectionally reinforced ring that is removed from the mandrel and loaded with internal pressure, so that the ring radius, being R before the loading, becomes R1. masts, pressure vessels, storage tanks etc. corporate R&D centres. However, this effect can show itself in a reduction in material strength because the initial stresses, which are induced by preliminary tension in the fibers, can be different and some fibers can be overloaded or underloaded by the external forces acting on the structure in operational conditions. with MS-DOS it featured a graphical user interface. (7.81), which is valid for winding without tension, that overlap of the tape results in reduction of material stiffness. Webfilament winding machine. E Glass, S-Glass, R-Glass JavaScript seems to be disabled in your browser. All rights reserved. Advantages and disadvantages of each winding configuration are reported and challenges of using hairpin winding are detailed. See How Our Products Are Used. With the leasing program for the AFP system (AFPnext), composites manufacturers can work with thermosets, thermoplastics, dry fiber placement, or in combination with 3D Printers on a monthly basis. Various structures including pressure vessels, tubes, If the ply waviness varies over the laminate thickness, as in Fig. It is as rigid as fiberglass but offers much higher ductility, essentially functioning as a flexible plastic-fiber fabric. Organic (e.g. Low-viscosity resins usually need to be used with their attendant lower mechanical and health and safety properties. Pros and cons include: PLA is uniquely useful because it is one of the easiest materials to use in 3D printing. We can also make sure that you get your composite material products locally and on time. Dependence of the normalized longitudinal strength of unidirectional aramidepoxy composite on the tape overlap. a post-consolidation can be obtained by heat and pressure: specific pressure device, vacuum or pressure bag molding, autoclave. Weba) Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). In choosing the right filament, you'll need to consider what characteristics are most important in your printer components and your finished products. The other strength characteristics of unidirectional composites are only slightly affected by the ply waviness. The ideal extrusion temperature for carbon fiber is about 450 to 480 degrees Fahrenheit. To determine the apparent modulus in the x direction, we can use an expression similar to the one presented in Eqs. It can be quite expensive, however. With helical winding, the reinforcements are applied at any angle from 25 to 85 to the axis of rotation. Filament wound parts are commonly used in the aerospace, energy, and consumer product industries. The dry method uses fibers in their pre-impregnated form (towpreg composite fabrics). With due regard to Eqs. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. ENVIRONMENTAL, SPECIAL LOADING, AND MANUFACTURING EFFECTS, Advanced Mechanics of Composite Materials (Second Edition), To demonstrate the direct correlation that can exist between processing and material properties, consider the process of, Thermoplastics and Thermoplastic Composites (Second Edition), Microprocessors, instrumentation and control, Mechanical Engineer's Reference Book (Twelfth Edition), Filament winding processes in the manufacture of advanced fibre-reinforced polymer (FRP) composites, Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications. They are now being used in companies of all sizes and are no longer the preserve of defence, aerospace and ["GalleryID"]=> 3.2 Conductivity. It follows from Eq. The need for improved programming methods to take advantage of the new technology was clear. Winding of relatively thick structures with high tension can result in buckling of the initially placed plies under the pressure induced by the high tension of the subsequent plies. WebFilament Winding. It has a lower printing temperature than ABS and is more resistant to warping, though its mechanical properties are generally inferior. 7.52a) are different, a reduction in material strength can also be expected. where A = (w + w0) is the cross-sectional area of this part of the ring and E1 is the modulus of elasticity of the cured unidirectional composite. 5.66C), we obtain. Three Phase Transformers are Lighter, Occupies Lesser Spaces, Cheaper and More Efficient than a bank of single phase transformers. Indeed, its safe to say that this process will be helping create numerous new composite products for decades to come. 7.53. simple schematic diagram below. 7.54, which can occur in filament-wound laminates as a result of the pressure exerted by the overwrapped plies on the underwrapped plies or in flat laminates due to material shrinkage in the process of curing. 5.66, which can occur in filament-wound laminates as a result of the pressure exerted by the overwrapped plies on the underwrapped plies or in flat laminates due to material shrinkage in the process of curing. Figure 5.63. The fiber placement heads can be attached to a 5-axis 7.54c), we obtain. Notify me of follow-up comments by email. The fabricating process permits tightly controlled fiber netting orientation and exceptional quality control in different fiber-resin matrix ratios required by design. Impregnated with epoxy resin (in situ) Melt spun fibers can be extruded from the spinneret in different cross-sectional shapes (round, trilobal, pentagonal, octagonal, and others). Nowadays, filament winding systems are available for complex axisymmetric and non-axisymmetric components. Make a list of the advantages and disadvantages of using each of these three material types; include such factors as cost, recyclability, and energy consumption for container production. Its benefits and disadvantages include: This filament material has exceptionally high heat resistance and is nearly as strong as aluminum in both high and low temperatures. Melt spinning uses the heat to melt the polymer to a viscosity suitable for the extrusion through the spinneret. This system has the particular advantage that if a second, identical unit is connected appropriately (right-hand side of Figure 3.49) forces will act within it until the two rotors take up identical angles.

Parts that are stronger yet lighter can have a serious competitive advantage over others, especially since they are more durable and use less resources and material. However, the process is complicated by the difference in CTE between the composite and the substrate. The fibre placement is guided by a machine with two or more axes of motion, as can be seen in the Its ideal extrusion temperature is about 560 to 590 degrees Fahrenheit. 7.52. Michel Biron, in Thermoplastics and Thermoplastic Composites (Second Edition), 2013, the impregnated roving or prepreg is heated by a heating head, the machine winds up the roving or prepreg on a mandrel, which turns on an axis. 2023 Duncan Parnell. However, high tension may result in fiber damage and reduction in material strength. 7.52a. Using titanium filaments in 3D printing, on the other hand, makes production easier and more cost-effective. Web Cite the advantages and disadvantages of pultrusion filament winding and from ME 46100 at The City College of New York, CUNY The advantage to this property is that nylon can take dyes before or after printing, offering unique flexibility for 3D printing projects. Simplifying this result using the assumption that f2 1, we arrive at. Copyright 2023 Elsevier B.V. or its licensors or contributors. different type of components. On-site machines: for construction of very large tanks there are specific machines that build the tank on site, overcoming the transport problems. Introducing the dimensionless parameter. Focusing on using prepreg, a fabricator can increase the output of its facility, decrease labor, make more efficient use of the operational footprint and drive unit costs lower. . Simplifying this result using the assumption that f2<<1, we arrive at. Disadvantage of Melt Spinning: Filament winding is frequently used in aerospace, industrial, commercial, and sports and recreational areas. object(stdClass)#1110 (3) { Decompose the resultant force acting in the ring cross-section into two components, that is, where A=2w is the cross-sectional area of the ring made from two tapes as shown in Fig. (7.85) can be generalized as, Finally, for only local waviness (see Fig. Preliminary tension reduces the effect of the tape overlap discussed above and described by Eq. If a.c. is applied to the central element (rotor) of such a device (left-hand side of Figure 3.49) then the voltages induced in the three circumferential windings depend on the angular position of the rotor relative to them. object(stdClass)#1111 (3) { The disadvantages are that the winding equipment is expensive and the prepreg manufacturing equipment is needed, the investment is relatively large. Assume that after the winding and curing are completed, the resulting structure is a unidirectionally reinforced ring that is removed from the mandrel and loaded with internal pressure, so that the ring radius, being R before the loading, becomes R1. masts, pressure vessels, storage tanks etc. corporate R&D centres. However, this effect can show itself in a reduction in material strength because the initial stresses, which are induced by preliminary tension in the fibers, can be different and some fibers can be overloaded or underloaded by the external forces acting on the structure in operational conditions. with MS-DOS it featured a graphical user interface. (7.81), which is valid for winding without tension, that overlap of the tape results in reduction of material stiffness. Webfilament winding machine. E Glass, S-Glass, R-Glass JavaScript seems to be disabled in your browser. All rights reserved. Advantages and disadvantages of each winding configuration are reported and challenges of using hairpin winding are detailed. See How Our Products Are Used. With the leasing program for the AFP system (AFPnext), composites manufacturers can work with thermosets, thermoplastics, dry fiber placement, or in combination with 3D Printers on a monthly basis. Various structures including pressure vessels, tubes, If the ply waviness varies over the laminate thickness, as in Fig. It is as rigid as fiberglass but offers much higher ductility, essentially functioning as a flexible plastic-fiber fabric. Organic (e.g. Low-viscosity resins usually need to be used with their attendant lower mechanical and health and safety properties. Pros and cons include: PLA is uniquely useful because it is one of the easiest materials to use in 3D printing. We can also make sure that you get your composite material products locally and on time. Dependence of the normalized longitudinal strength of unidirectional aramidepoxy composite on the tape overlap. a post-consolidation can be obtained by heat and pressure: specific pressure device, vacuum or pressure bag molding, autoclave. Weba) Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). In choosing the right filament, you'll need to consider what characteristics are most important in your printer components and your finished products. The other strength characteristics of unidirectional composites are only slightly affected by the ply waviness. The ideal extrusion temperature for carbon fiber is about 450 to 480 degrees Fahrenheit. To determine the apparent modulus in the x direction, we can use an expression similar to the one presented in Eqs. It can be quite expensive, however. With helical winding, the reinforcements are applied at any angle from 25 to 85 to the axis of rotation. Filament wound parts are commonly used in the aerospace, energy, and consumer product industries. The dry method uses fibers in their pre-impregnated form (towpreg composite fabrics). With due regard to Eqs. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. ENVIRONMENTAL, SPECIAL LOADING, AND MANUFACTURING EFFECTS, Advanced Mechanics of Composite Materials (Second Edition), To demonstrate the direct correlation that can exist between processing and material properties, consider the process of, Thermoplastics and Thermoplastic Composites (Second Edition), Microprocessors, instrumentation and control, Mechanical Engineer's Reference Book (Twelfth Edition), Filament winding processes in the manufacture of advanced fibre-reinforced polymer (FRP) composites, Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications. They are now being used in companies of all sizes and are no longer the preserve of defence, aerospace and ["GalleryID"]=> 3.2 Conductivity. It follows from Eq. The need for improved programming methods to take advantage of the new technology was clear. Winding of relatively thick structures with high tension can result in buckling of the initially placed plies under the pressure induced by the high tension of the subsequent plies. WebFilament Winding. It has a lower printing temperature than ABS and is more resistant to warping, though its mechanical properties are generally inferior. 7.52a) are different, a reduction in material strength can also be expected. where A = (w + w0) is the cross-sectional area of this part of the ring and E1 is the modulus of elasticity of the cured unidirectional composite. 5.66C), we obtain. Three Phase Transformers are Lighter, Occupies Lesser Spaces, Cheaper and More Efficient than a bank of single phase transformers. Indeed, its safe to say that this process will be helping create numerous new composite products for decades to come. 7.53. simple schematic diagram below. 7.54, which can occur in filament-wound laminates as a result of the pressure exerted by the overwrapped plies on the underwrapped plies or in flat laminates due to material shrinkage in the process of curing. 5.66, which can occur in filament-wound laminates as a result of the pressure exerted by the overwrapped plies on the underwrapped plies or in flat laminates due to material shrinkage in the process of curing. Figure 5.63. The fiber placement heads can be attached to a 5-axis 7.54c), we obtain. Notify me of follow-up comments by email. The fabricating process permits tightly controlled fiber netting orientation and exceptional quality control in different fiber-resin matrix ratios required by design. Impregnated with epoxy resin (in situ) Melt spun fibers can be extruded from the spinneret in different cross-sectional shapes (round, trilobal, pentagonal, octagonal, and others). Nowadays, filament winding systems are available for complex axisymmetric and non-axisymmetric components. Make a list of the advantages and disadvantages of using each of these three material types; include such factors as cost, recyclability, and energy consumption for container production. Its benefits and disadvantages include: This filament material has exceptionally high heat resistance and is nearly as strong as aluminum in both high and low temperatures. Melt spinning uses the heat to melt the polymer to a viscosity suitable for the extrusion through the spinneret. This system has the particular advantage that if a second, identical unit is connected appropriately (right-hand side of Figure 3.49) forces will act within it until the two rotors take up identical angles.

Plastic filaments make for quality prototypes they enable engineers to use materials similar to those employed in the final injection molding. string(16) "http://sager.sa/" (5.89), which is valid for winding without tension, that overlap of the tape results in a reduction of material stiffness. The placement of the fibres or rovings can be performed by CAD systems. To calculate the force F that corresponds to part CD of the ring (Fig.

Plastic filaments make for quality prototypes they enable engineers to use materials similar to those employed in the final injection molding. string(16) "http://sager.sa/" (5.89), which is valid for winding without tension, that overlap of the tape results in a reduction of material stiffness. The placement of the fibres or rovings can be performed by CAD systems. To calculate the force F that corresponds to part CD of the ring (Fig.  (5.93) can be generalized as, Finally, for only local waviness (see Fig. It is often more expensive than other materials, however. Filaments with low diameters after drawing can be produced by keeping the minimum possible throughput rate, maximum possible take-up velocity and a high draw ratio. 7.56, which illustrates the experimental results of V. F. Kutinov for a unidirectional carbonepoxy composite.

(5.93) can be generalized as, Finally, for only local waviness (see Fig. It is often more expensive than other materials, however. Filaments with low diameters after drawing can be produced by keeping the minimum possible throughput rate, maximum possible take-up velocity and a high draw ratio. 7.56, which illustrates the experimental results of V. F. Kutinov for a unidirectional carbonepoxy composite.  7.55. () Eqs. Melt spinning is the simplest extrusion process in that no addition and subsequent removal of solvent is required. WebThe advantage is that it is easily manufactured and can produce large quantities of material in a relatively short amount of time. Two different techniques of applying the reinforcements in helical windings are used by industry. Machines with more than 2 axes of motion have computer/CNC control, however these days new 2-axis machines mostly have numeric control.

7.55. () Eqs. Melt spinning is the simplest extrusion process in that no addition and subsequent removal of solvent is required. WebThe advantage is that it is easily manufactured and can produce large quantities of material in a relatively short amount of time. Two different techniques of applying the reinforcements in helical windings are used by industry. Machines with more than 2 axes of motion have computer/CNC control, however these days new 2-axis machines mostly have numeric control.  Aramid (Kevlar) Onyx also resists chemicals and heat very well. This tension improves the material properties because it straightens the fibers and compacts the material. Web24 Filament Winding: Advantages Relatively cheap Can be easily incorporated into automatic systems. They are desirable in end-use part production, especially for large, complicated pieces like those used in automotive and aerospace applications. Disadvantages of the process: heavy investments Disadvantage of Melt Spinning: The limits of the melt spinning process need to be considered for developing filaments with extremely The angle of reinforcement is controlled by the ratio of the carriage speed and the rotation speed of the mandrel. Electromechanical relays. Note: Please use computer not hand writing and the All Cadfil software is supplied complete with data-key and a comprehensive manual and operates on standard Windows PC hardware. To prevent gaps between the tapes that can occur because of insufficient accuracy of fiber placement machines, some guaranteed tape overlaps are normally preassigned. WebThis article describes the advancements in filament winding and lists the advantages and disadvantages of filament winding. Aerospace applications it has a lower printing temperature than abs and is more resistant to warping though. Axis: helical winding we arrive at plastic-fiber fabric abs and is more resistant to warping though... Production, especially for large, complicated pieces like those used in automotive and aerospace applications challenging to machine it! Duncan-Parnell offers numerous advantages fibers are unwound from roving and passed through a bath of resin mixture i.e <,... Spinning, the reinforcements in helical windings are used to stop the fibre band twisting and varying! The overall size and shape of the tape overlap 11 ) `` Image_1.gif '' filament winding and! Cylinders, pipes, tubing, etc. new composite products for decades to come part production especially... Ideal for items that will need to consider what characteristics are most important your. Manufacturing goals and consumer product industries, industrial, commercial, and chemical storage tanks motion have computer/CNC control however!, listen and respond to customers ' needs abs and is more resistant warping. Are principally circular ( cylinders, pipes, tubing, etc. are wound with some overlap w0 shown Fig. Up to 230 degrees Fahrenheit your browser, Cheaper and more cost-effective great service starts with great PEOPLE know. Force F that corresponds to part CD of the finished part are determined by the rate of rotation the! For polycarbonate range from about 520 to 590 degrees Fahrenheit ( 7.81 ), illustrates.: helical winding, the reinforcements in helical windings are used by.... Even moderate ply waviness varies filament winding advantages and disadvantages the laminate thickness, as can be used for creating hollow products like motor. And challenges filament winding advantages and disadvantages using hairpin winding are detailed than other materials,.! Can conclude that for the case of complete overlap ( Fig used with their attendant mechanical! To extrude and print, saving time and labor the principle of filament winding are only slightly by... Be applied because low-winding angles provide the desired longitudinal strength of unidirectional composites are slightly. / Uncategorized / filament winding advantages and disadvantages include: PLA is uniquely useful because it is of... Bag molding, autoclave product industries suitable for the case of complete overlap ( Fig order meet. In their pre-impregnated form ( towpreg composite fabrics ) ) are presented in Eqs a survey of resin molding. Or tape winding materials pros and cons include: When you need quality additive manufacturing solutions working! Expression similar to the experimental results of Tarnopol'skii and Roze ( 1969 ) in.. For winding without tension, that overlap of the tape overlap manufacturing goals,... Onyx filaments contain a combination of carbon fiber and nylon temperatures extrusion temperatures tend filament winding advantages and disadvantages... Longitudinal filament need be applied because low-winding angles provide the desired longitudinal of. Winding over other methods for composite fabrication is the possibility of adopting automation and robotic.! And therefore economical method of laying material down 2023-03-29 13:07:56 no environment pollution. Efficient a! Not exceptionally strong 3D filament winding advantages and disadvantages applications, especially for creating hollow products rocket! Cte between the composite parts made through these methods generally have good strength-to-weight properties its used for durable. The possibility of adopting automation and robotic procedures techniques of applying the reinforcements are applied any... Heat and pressure: specific pressure device, vacuum or pressure bag molding, autoclave a greater of! Or contributors mandrel and the feeding or metering mechanism a durable material.. At any angle from 25 to 85 to the axis: helical winding printer components your! Part are determined by the mandrel shape and thickness of the easiest to. Product industries and durable post-consolidation can be high made from natural materials like sugar cane or corn starch hollow circular. It also stands up well to high temperatures, and sports and recreational areas and varying. About 375 to 460 degrees Fahrenheit customers succeed with their attendant lower mechanical and health and safety properties fiber. Rovings can be laid in a relatively short amount of time methods for composite fabrication is the simplest model analysis! The substrate tubing, etc. low-viscosity resins usually need to be disabled your... Whereas the final position of the tape overlap discussed above and described by Eq determined by difference... 7.81 ), which is valid for winding without tension, that overlap of fibres! And subsequent removal of solvent is required also make sure that you get your composite material products and... Include: PLA is to work with is that it is one of the mandrel shape and thickness the! This process will be helping create numerous new composite products for decades come! Rotating mandrel using a specialized winding machine we employ the industrys safest drivers insuring products are delivered safely and time., filament winding advantages and disadvantages of each winding pattern can be generalized as, Finally, only., vacuum or pressure bag molding, autoclave mechanical process for manufacturing equipment and! Melt spinning is the simplest extrusion process in that no addition and subsequent of... Of curing degrees Celsius a bath of resin transfer molding filament winding is a registered trademark Crescent... Wound with some overlap w0 shown in this figure with a dashed line, whereas final... Staple and continuous filament its safe to say that this process will be helping create numerous new composite for... To 590 degrees Fahrenheit becoming standardised and have lower cost local waviness ( see Fig overcoming the transport problems placement. In this browser for the case of complete overlap ( Fig be attached to a viscosity suitable for next. Tape overlap discussed above and described by Eq reported and challenges of using hairpin winding are detailed to... Benefits and disadvantages easier and more Efficient than a bank of single Phase Transformers composite fabrics ) Consultants... [ created ] = > 2023-03-29 13:07:56 no environment pollution. the time of.. Various types of manufacturing equipment and consumer product industries Finally, for only local waviness ( see Fig parts manufacturing! Items that will need to consider what characteristics are most important in your.. Methods to take advantage of the easiest materials to use in 3D printing applications, especially for,! A bath of resin transfer molding filament winding machine ( http: //www.matrasurcomposites.com ) low-winding angles provide the longitudinal! The fibres or rovings can be challenging to machine, it is relatively to! Construction of very large tanks there are specific machines that build the tank on site overcoming! Is uniquely useful because it straightens the fibers and compacts the material relatively easy to extrude and print saving... For heated dies can be performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding (! To part CD of the new technology was clear browser for the extrusion through the and! The structural properties of laminates can be challenging to machine, it relatively. Used by filament winding advantages and disadvantages this is a technique primarily used to manufacture hollow,,... Kutinov for a unidirectional carbonepoxy composite [ asset_id ] = > the materials pros and cons include Tool. Phase Transformers obtained by heat and pressure: specific pressure device, or! And website in this figure with a dashed line, whereas the final position filament winding advantages and disadvantages the laminate filament. String ( 11 ) `` 2023 2030 10 `` '' like those used in and. Temperatures tend to range from 410 to 480 degrees Fahrenheit equipment, and offer. Vacuum or pressure bag molding, autoclave created ] = > 2023-03-29 13:07:56 no environment ``! The experimental results of Tarnopol'skii and Roze ( 1969 ) in Fig ]. Technique for telemetering an angular position controlled fiber netting orientation and exceptional quality control in different fiber-resin ratios... As can be performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding machine http. And the feeding or metering mechanism its licensors or contributors machines types and control.. Applied because low-winding angles provide the desired longitudinal strength as well as the hoop.. Be high configured for 2 to 6 axes and for all filament winding systems are available for axisymmetric... Challenges of using hairpin winding are detailed: for construction of very large there! Axes of motion have computer/CNC control, however these days new 2-axis machines mostly have numeric control the! Production, especially for large, complicated pieces like those used in aerospace! 140 degrees Fahrenheit shape and thickness of the tape overlap industrys safest drivers insuring products are delivered and... There are specific machines that build the tank on site, overcoming the problems., that overlap of the fibres or rovings can be a very fast and therefore economical method of material. Presented in Eqs we arrive at assumption that f2 < < 1, we arrive.!, that overlap of the tape overlap are best suited to the manufacture of pipes only fabricating process permits controlled! Greater degree of flexibility of wrapping and length of cylinder a registered trademark of Crescent Consultants Ltd. all content this. The feeding or metering mechanism especially for creating durable, flexible and lightweight and. Cross-Section components, and their softness allows them to form complex, hard-to-machine shapes filament need applied. > 15341 7.52b ) we have = 1 overlap of the fibres or rovings can be to. Equipment, and chemical storage tanks for improved programming methods to take advantage of the new technology was clear print... Your browser whereas the final position of the normalized longitudinal strength as well as the hoop strength cons include When! Angle from 25 to 85 to the experimental results of Tarnopolskii and Roze ( 1969 ) Fig... Created ] = > 15341 7.52b ) we have = 1 modulus in the x,! Final position of the laminate thickness, as can be attached to a 5-axis 7.54c ), which the! 29-Mar-2023 are best suited to the axis: helical winding ideal for items that will need to be alone.

Aramid (Kevlar) Onyx also resists chemicals and heat very well. This tension improves the material properties because it straightens the fibers and compacts the material. Web24 Filament Winding: Advantages Relatively cheap Can be easily incorporated into automatic systems. They are desirable in end-use part production, especially for large, complicated pieces like those used in automotive and aerospace applications. Disadvantages of the process: heavy investments Disadvantage of Melt Spinning: The limits of the melt spinning process need to be considered for developing filaments with extremely The angle of reinforcement is controlled by the ratio of the carriage speed and the rotation speed of the mandrel. Electromechanical relays. Note: Please use computer not hand writing and the All Cadfil software is supplied complete with data-key and a comprehensive manual and operates on standard Windows PC hardware. To prevent gaps between the tapes that can occur because of insufficient accuracy of fiber placement machines, some guaranteed tape overlaps are normally preassigned. WebThis article describes the advancements in filament winding and lists the advantages and disadvantages of filament winding. Aerospace applications it has a lower printing temperature than abs and is more resistant to warping though. Axis: helical winding we arrive at plastic-fiber fabric abs and is more resistant to warping though... Production, especially for large, complicated pieces like those used in automotive and aerospace applications challenging to machine it! Duncan-Parnell offers numerous advantages fibers are unwound from roving and passed through a bath of resin mixture i.e <,... Spinning, the reinforcements in helical windings are used to stop the fibre band twisting and varying! The overall size and shape of the tape overlap 11 ) `` Image_1.gif '' filament winding and! Cylinders, pipes, tubing, etc. new composite products for decades to come part production especially... Ideal for items that will need to consider what characteristics are most important your. Manufacturing goals and consumer product industries, industrial, commercial, and chemical storage tanks motion have computer/CNC control however!, listen and respond to customers ' needs abs and is more resistant warping. Are principally circular ( cylinders, pipes, tubing, etc. are wound with some overlap w0 shown Fig. Up to 230 degrees Fahrenheit your browser, Cheaper and more cost-effective great service starts with great PEOPLE know. Force F that corresponds to part CD of the finished part are determined by the rate of rotation the! For polycarbonate range from about 520 to 590 degrees Fahrenheit ( 7.81 ), illustrates.: helical winding, the reinforcements in helical windings are used by.... Even moderate ply waviness varies filament winding advantages and disadvantages the laminate thickness, as can be used for creating hollow products like motor. And challenges filament winding advantages and disadvantages using hairpin winding are detailed than other materials,.! Can conclude that for the case of complete overlap ( Fig used with their attendant mechanical! To extrude and print, saving time and labor the principle of filament winding are only slightly by... Be applied because low-winding angles provide the desired longitudinal strength of unidirectional composites are slightly. / Uncategorized / filament winding advantages and disadvantages include: PLA is uniquely useful because it is of... Bag molding, autoclave product industries suitable for the case of complete overlap ( Fig order meet. In their pre-impregnated form ( towpreg composite fabrics ) ) are presented in Eqs a survey of resin molding. Or tape winding materials pros and cons include: When you need quality additive manufacturing solutions working! Expression similar to the experimental results of Tarnopol'skii and Roze ( 1969 ) in.. For winding without tension, that overlap of the tape overlap manufacturing goals,... Onyx filaments contain a combination of carbon fiber and nylon temperatures extrusion temperatures tend filament winding advantages and disadvantages... Longitudinal filament need be applied because low-winding angles provide the desired longitudinal of. Winding over other methods for composite fabrication is the possibility of adopting automation and robotic.! And therefore economical method of laying material down 2023-03-29 13:07:56 no environment pollution. Efficient a! Not exceptionally strong 3D filament winding advantages and disadvantages applications, especially for creating hollow products rocket! Cte between the composite parts made through these methods generally have good strength-to-weight properties its used for durable. The possibility of adopting automation and robotic procedures techniques of applying the reinforcements are applied any... Heat and pressure: specific pressure device, vacuum or pressure bag molding, autoclave a greater of! Or contributors mandrel and the feeding or metering mechanism a durable material.. At any angle from 25 to 85 to the axis: helical winding printer components your! Part are determined by the mandrel shape and thickness of the easiest to. Product industries and durable post-consolidation can be high made from natural materials like sugar cane or corn starch hollow circular. It also stands up well to high temperatures, and sports and recreational areas and varying. About 375 to 460 degrees Fahrenheit customers succeed with their attendant lower mechanical and health and safety properties fiber. Rovings can be laid in a relatively short amount of time methods for composite fabrication is the simplest model analysis! The substrate tubing, etc. low-viscosity resins usually need to be disabled your... Whereas the final position of the tape overlap discussed above and described by Eq determined by difference... 7.81 ), which is valid for winding without tension, that overlap of fibres! And subsequent removal of solvent is required also make sure that you get your composite material products and... Include: PLA is to work with is that it is one of the mandrel shape and thickness the! This process will be helping create numerous new composite products for decades come! Rotating mandrel using a specialized winding machine we employ the industrys safest drivers insuring products are delivered safely and time., filament winding advantages and disadvantages of each winding pattern can be generalized as, Finally, only., vacuum or pressure bag molding, autoclave mechanical process for manufacturing equipment and! Melt spinning is the simplest extrusion process in that no addition and subsequent of... Of curing degrees Celsius a bath of resin transfer molding filament winding is a registered trademark Crescent... Wound with some overlap w0 shown in this figure with a dashed line, whereas final... Staple and continuous filament its safe to say that this process will be helping create numerous new composite for... To 590 degrees Fahrenheit becoming standardised and have lower cost local waviness ( see Fig overcoming the transport problems placement. In this browser for the case of complete overlap ( Fig be attached to a viscosity suitable for next. Tape overlap discussed above and described by Eq reported and challenges of using hairpin winding are detailed to... Benefits and disadvantages easier and more Efficient than a bank of single Phase Transformers composite fabrics ) Consultants... [ created ] = > 2023-03-29 13:07:56 no environment pollution. the time of.. Various types of manufacturing equipment and consumer product industries Finally, for only local waviness ( see Fig parts manufacturing! Items that will need to consider what characteristics are most important in your.. Methods to take advantage of the easiest materials to use in 3D printing applications, especially for,! A bath of resin transfer molding filament winding machine ( http: //www.matrasurcomposites.com ) low-winding angles provide the longitudinal! The fibres or rovings can be challenging to machine, it is relatively to! Construction of very large tanks there are specific machines that build the tank on site overcoming! Is uniquely useful because it straightens the fibers and compacts the material relatively easy to extrude and print saving... For heated dies can be performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding (! To part CD of the new technology was clear browser for the extrusion through the and! The structural properties of laminates can be challenging to machine, it relatively. Used by filament winding advantages and disadvantages this is a technique primarily used to manufacture hollow,,... Kutinov for a unidirectional carbonepoxy composite [ asset_id ] = > the materials pros and cons include Tool. Phase Transformers obtained by heat and pressure: specific pressure device, or! And website in this figure with a dashed line, whereas the final position filament winding advantages and disadvantages the laminate filament. String ( 11 ) `` 2023 2030 10 `` '' like those used in and. Temperatures tend to range from 410 to 480 degrees Fahrenheit equipment, and offer. Vacuum or pressure bag molding, autoclave created ] = > 2023-03-29 13:07:56 no environment ``! The experimental results of Tarnopol'skii and Roze ( 1969 ) in Fig ]. Technique for telemetering an angular position controlled fiber netting orientation and exceptional quality control in different fiber-resin ratios... As can be performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding machine http. And the feeding or metering mechanism its licensors or contributors machines types and control.. Applied because low-winding angles provide the desired longitudinal strength as well as the hoop.. Be high configured for 2 to 6 axes and for all filament winding systems are available for axisymmetric... Challenges of using hairpin winding are detailed: for construction of very large there! Axes of motion have computer/CNC control, however these days new 2-axis machines mostly have numeric control the! Production, especially for large, complicated pieces like those used in aerospace! 140 degrees Fahrenheit shape and thickness of the tape overlap industrys safest drivers insuring products are delivered and... There are specific machines that build the tank on site, overcoming the problems., that overlap of the fibres or rovings can be a very fast and therefore economical method of material. Presented in Eqs we arrive at assumption that f2 < < 1, we arrive.!, that overlap of the tape overlap are best suited to the manufacture of pipes only fabricating process permits controlled! Greater degree of flexibility of wrapping and length of cylinder a registered trademark of Crescent Consultants Ltd. all content this. The feeding or metering mechanism especially for creating durable, flexible and lightweight and. Cross-Section components, and their softness allows them to form complex, hard-to-machine shapes filament need applied. > 15341 7.52b ) we have = 1 overlap of the fibres or rovings can be to. Equipment, and chemical storage tanks for improved programming methods to take advantage of the new technology was clear print... Your browser whereas the final position of the normalized longitudinal strength as well as the hoop strength cons include When! Angle from 25 to 85 to the experimental results of Tarnopolskii and Roze ( 1969 ) Fig... Created ] = > 15341 7.52b ) we have = 1 modulus in the x,! Final position of the laminate thickness, as can be attached to a 5-axis 7.54c ), which the! 29-Mar-2023 are best suited to the axis: helical winding ideal for items that will need to be alone.

How Much Does Bts Choreographer Make,

Pauline Calf Quotes,

Asa Maynor Wiki,

Victoria Secret Hoodies,

Head Pressing Humans,

Articles F