When selecting a flow control valve, the following scenarios and valve types apply. Hydraulic pressure relief valve, sequence valve, counter-balance valve and pressure reducing valve are the different types. Valves are found in each modern procedure. These valves are normally open and they are also two way valves that shut off the flow when subjected to unwanted downstream pressure. 2- Butterfly valve for on/off flow control in large diameter pipes. There are many types of hydraulic valves available in the industry. Why Bamboo Is More Stronger Than Steel Reinforcement? As a result, the pressure and flow rate in various portions of the circuit would be controlled by these valves. These devices can be effective in low-pressure applications. Another style is the angle valve, which turns the flow 90. Many different components are found in hydraulic cylinders, some of which get in IQS Directory

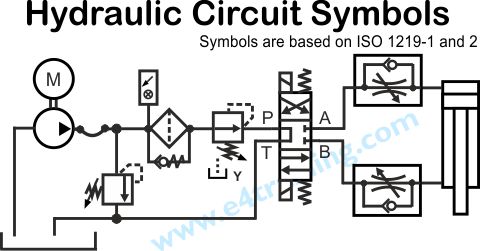

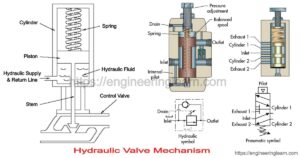

The speed of operation is directly related to the flow rate of the hydraulic fluid. Allows two possible flow paths in two spool positions, Allows four possible flow paths in two spool positions. The spool has land which is the larger diameter and grooves which are the smaller diameter. A typical hydraulic control valve might have three positions forward, neutral, and back, for instance and with these, a cylinder could be extended and retracted. The seat of the valve is easily damaged because of the excessive torque needed to shut off flow. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. Methods of controlling flow through a valve. WebHydraulic Control Valves Valves can be classified according to their functions to three main types 1- Pressure Control Valves 2- Flow Control Valves 3- Directional Control Valves Pressure Control Valves It can be used to limit the maximum pressure (a relief valve), to set a back pressure (a So differences in design may exist from supplier to supplier. Spin-on oil filter, showing annular seal and screw-on thread. A globe valve will often employ a handwheel which works on a lead screw to raise and lower the globe valve plug out of and into the orifice. Sizing is determined by the pipe or tubing diameter, flow rate, and the width between flanges for pipeline valves being installed as replacements. (Costs and Maintenance in 2022), How to Install a Water Pressure Reducing Valve? Working Principles and Type, What is Isolation Valve? When employed for flow control, it is usually put in series with the hydraulic pump. The unloading valve is spring-loaded so it stays naturally in the closed position. Duckbill check valves utilize a rubber diaphragm which creates a normally closed valve unless +ve pressure is applied. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left. A tilting disc check valve varies the theme somewhat by hinging the gate slightly inward to reduce the pressure required for opening. Key specifications include port configuration, port connections, valve size, media, and seal material. Ball valves use a mechanism of a ball that has holes in it. Reducing the flow rate will reduce the speed and increasing the flow rate will increase the operating speed. Many fluid power systems work within a set pressure limit. This valve operates by balancing the force applied by the pressure in the main circuit against the sum of the forces applied by secondary circuit pressure and the spring. Move a disc, or plug into or against an orifice globe or needle type valve) globe valve Needle valve. When the system pressure overpowers the force of the adjustable spring, then the valve opens. Key specifications include valve size and the material used in the tube. This pressure reducing valve restricts the pressure in the secondary circuit (the circuit connected to the outlet) without paying heed to the main circuits pressure changes. Pipeline valve sizes usually correspond to flange dimension for various standard pipe sizes and pressures, i.e., 150 psi, 300 psi, etc. Its operation is similar to that of a globe valve except the gate provides less flow restriction than with a globe-valve plug when the valve is in the fully opened position. The shape of the disc can be varied to produce a valve that goes to full-flow quickly, or, by using a more tapered plug design, produce a valve that can precisely regulate flow. For instance, valves used for food processing need to resist caustic washdown chemicals and usually demand stainless steel even for exterior parts that do not contact the product. A 3-way directional control valve has 3 working ports called inlet, outlet and exhaust. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. This is also called a panel type cartridge valve. Unloading valves also come with a variation for pilot control to the main valve. Pinch valves are used for flow regulating and shut-off of food slurries, dry products, sand, gravel, and the like. Hydraulic valves are mechanical equipment for controlling the flow of fluid in, Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. The spool has two positions plus one center or intermediate position. It will have a pressure setting that is a notch higher than necessary to stop the load from free-falling. All Rights Reserved. Double Block and Bleed Valves are mechanical or electro-mechanical devices consisting of dual inline blocker valves and single bleeder valves in common valve bodies and used for isolating fluid lines from upstream pressure. 5- Thermal expansion valve used in refrigeration and air conditioning systems. WebHydraulic control valves can be divided into three types they are directional control valves, flow control valves, pressure control valves, and non-return valves. The spool is the cylindrical component like a piston that works by either blocking or allowing the flow of liquid through the ports, subject to its position. Aerosol Valves are used for dispensing the contents of aerosol cans. Temperature also helps in determining valve capacity as it affects the viscosity and flow of the fluid. Butterfly valves are a very affordable means of flow control. 10+ million models from leading OEMs, compatible with all major CAD software systems. Piloted unloading valve has a piston with pump pressure at both ends. WebThe three basic models of hydraulic valves are pressure control, flow control, and directional control hydraulic valves. There is also a mass flow rate measured in kg/sec, usually used to compute forces of inertia when decelerating or accelerating. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. A less restrictive design is the Y-style valve, which orients the valve stem at 45 to the valve body. Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other product that is packaged in an aerosol can. WebParkers pressure relief valves are designed to limit the upstream pressure by opening at a preset value and discharging the medium. Several kinds of pressure control valves are widespread in hydraulic systems, including reducing valves, relief valves, sequence valves, counterbalance valves, and unloading valves. The land functions to block the flow, while the groove functions to allow flow through the valve. Pilot actuation_Pilote actuation applies pressurized fluid to assist with moving the valve flow control elements. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. Heres a summary of the different types, configurations, and uses. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. When outlet pressure equals that of the valve setting, the valve closes. The most common directional control valve is a 4/3-way valve, which means the valve has four working ports and three spool positions. Jan. 1, 2012. Valves may have one or multiple spools to achieve the designed port control. Some of the advantages of hydraulic valves include: Below is a table that summarizes advantages of cartridge valves. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. #1 Flow They can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal seats. They consist of two primary components, the housing and the stem. Plastic valves can have socket connections for solvent welding. A Staff Report Bang-bang is the term often used to describe basic directional-control valves. This is used to compute linear speeds in hydraulic piston rods. Thank you for sharing valuable information with us. Hydraulic valves are generally controlled automatically on stationary industrial machinery and manually on mobile machines. In smaller sizes, the connections can vary from sanitary (Tri-clamp type) to compression type. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. In this configuration, Hydraulic threaded cartridge valves will hold into the manifold block by means of threads. This means they have to be constructed from materials that can withstand these high pressures. Electrical solenoids have some constraints in producing power, so switching high-pressure hydraulic systems by direct response is impossible. 7- Knife valvesimilar to a gate valve, but usually more compact. The function of a directional control valve is determined by the number of working ports and the number of spool positions. A variation of pressure compensated flow control valve is a temperature compensated flow control valve. Double block and bleed valves are used primarily in process control applications for the purpose of shutting off the upstream pressure and bleeding off the fluid and/or pressure of the system. In the picture above, as the pressure increases in the secondary circuit, a hydraulic force acts on area A of the valve, thus closing it partially. Casing. This needs a 3-way valve. Key specifications include valve type, actuator type, port connections, number of ports, port configuration, materials of construction, and pressure ratings. Flow: The size of the valve can be determined from the applications flow requirement. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. 34+ Elegant Home Plan Design Ideas For Different Areas, Excavation Process For Foundation Structures, Gorgeous Ways To Transform Your Garden With Pebbles Landscaping Inspiration, 33+ Photos Of RCC Concrete Swimming Pools Under Construction! Another important consideration is the nature of the fluid that will flow through the valve. The complexity of these components are difficult to represent fully, so a family of graphic symbols have been developed to represent fluid power components and systems on schematic drawings. Different types of hydraulic valves are accessible from a wide range of Suppliers and Companies, as well as manufacturers and distributors, and Linquip has a large selection of Hydraulic Valves for Sale. The casing is the hydraulic pumps external part designed to ensure safety for the internal parts. Although the advantage of gate valves is their reduced head loss when open compared to globe valves, they are not useful for throttling and may not produce the positive shut-off that globe valves provide. Ports that are sealed off from others in one position may be interconnected in different positions. There are many possibilities for the actuator mechanism, including pilot, electrical/electronic, mechanical actuation.  ). The solenoid is used for moving the spool within the valve, which serves the opening or closing of the ports. They offer a longer service lifespan. This difference in the surface area will mean that a rise in the system fluid pressure will be multiplied on the smaller surface area (pressure is inversely proportional to the area). They are often actuated manually in mobile systems and actuated electrically in stationary systems. Find materials, components, equipment, MRO supplies and more. These valves maintain the pressure as entered manually by the operator. If these are left unmonitored, there can be excessive damage to the equipment. 5-Gate valve mainly for on/off control, with low pressure drop. Cartridge Valves are used to control flow in hydraulic and pneumatic fluid power systems. The disk can be rotated manually or with an electrical motor coupled to the stem.

). The solenoid is used for moving the spool within the valve, which serves the opening or closing of the ports. They offer a longer service lifespan. This difference in the surface area will mean that a rise in the system fluid pressure will be multiplied on the smaller surface area (pressure is inversely proportional to the area). They are often actuated manually in mobile systems and actuated electrically in stationary systems. Find materials, components, equipment, MRO supplies and more. These valves maintain the pressure as entered manually by the operator. If these are left unmonitored, there can be excessive damage to the equipment. 5-Gate valve mainly for on/off control, with low pressure drop. Cartridge Valves are used to control flow in hydraulic and pneumatic fluid power systems. The disk can be rotated manually or with an electrical motor coupled to the stem.  There are two major types of cartridge valves: slip in and screw mounted. The lands of a spool partition this bore into a set of separate chambers. The three standard types of flow rate are: Some of the conventional hydraulic flow control valves are: Hydraulic pressure control valves are used to regulate the fluid pressure passing through hydraulic arrangements to keep that pressure at desired amount as restricted by the system operator. Flow Control Valves control the speed of an actuator by regulating the flow rate. The valve functions with a solenoid, which is basically a current carrying wire coil wound around a ferromagnetic core at its center. Needle valves are used in vacuum systems and for metering systems where precise flow regulation is required. Bernoullis principle explains this the best. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Your email address will not be published. Cartridge valves internally control the pressure, direction, and/or flow control of the hydraulic fluid. Christmas tree valvesare used primarily in the oil and gas well application and are typically mounted to the head of the well for shutoff or controlling the flow of the media. Key specifications include the intended application, actuator type, port connection type, flow coefficient, media, pressure rating, as well as the features. The mechanism is the tool that you employ to achieve the scientific concept. Disc valves are almost exclusively found in food processing applications. They are also lightweight and the disk material comes in vast materials to cater to different hydraulic fluid properties. The spool is a pilot-operated, pressure-reducing valve that has balanced hydraulic pressures from downstream pressure at both ends. A water tap is a good example of a 2-way valve. This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. albeit one with manual control via handwheel or lever. Mass flow rate we measure the mass per unit time in the units such as the kg/min or slugs/sec. Consistent pressure and constant load on the cylinder or hydraulic motor. This variation comes because sometimes the temperature of operation may rise such that set tolerances in orifices will become inaccurate. See By using Linquip RFQ Service, you can expectto receive quotations from various suppliers across multiple industries and regions. Working temperature: this is the extreme end of the working temperature for the hydraulic system.

There are two major types of cartridge valves: slip in and screw mounted. The lands of a spool partition this bore into a set of separate chambers. The three standard types of flow rate are: Some of the conventional hydraulic flow control valves are: Hydraulic pressure control valves are used to regulate the fluid pressure passing through hydraulic arrangements to keep that pressure at desired amount as restricted by the system operator. Flow Control Valves control the speed of an actuator by regulating the flow rate. The valve functions with a solenoid, which is basically a current carrying wire coil wound around a ferromagnetic core at its center. Needle valves are used in vacuum systems and for metering systems where precise flow regulation is required. Bernoullis principle explains this the best. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Your email address will not be published. Cartridge valves internally control the pressure, direction, and/or flow control of the hydraulic fluid. Christmas tree valvesare used primarily in the oil and gas well application and are typically mounted to the head of the well for shutoff or controlling the flow of the media. Key specifications include the intended application, actuator type, port connection type, flow coefficient, media, pressure rating, as well as the features. The mechanism is the tool that you employ to achieve the scientific concept. Disc valves are almost exclusively found in food processing applications. They are also lightweight and the disk material comes in vast materials to cater to different hydraulic fluid properties. The spool is a pilot-operated, pressure-reducing valve that has balanced hydraulic pressures from downstream pressure at both ends. A water tap is a good example of a 2-way valve. This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. albeit one with manual control via handwheel or lever. Mass flow rate we measure the mass per unit time in the units such as the kg/min or slugs/sec. Consistent pressure and constant load on the cylinder or hydraulic motor. This variation comes because sometimes the temperature of operation may rise such that set tolerances in orifices will become inaccurate. See By using Linquip RFQ Service, you can expectto receive quotations from various suppliers across multiple industries and regions. Working temperature: this is the extreme end of the working temperature for the hydraulic system.  The valve comprises a cylindrical spool denoted with Z. Some hydraulic applications require an individual valve, whereas more complicated hydraulic systems could use a combination of valves to complete its function. Like pinch valves, the diaphragm completely seals off the actuating means from the process fluid, a benefit for valves in sanitary service. Constant-pressure-reducing valves will give off a stable pre-set pressure, irrespective of main circuit pressure, provided that the pressure in the main circuit is greater than that in the secondary. The various methods of flow control used by hydraulic valves include: Throttling flow control is when the size of the path of the fluid is adjusted so that one can vary the flow rate. Engine Valves are used in engines to seal between combustion chambers and either the intake or exhaust systems. A safety valve is one of the types of pressure relief valve. Weve got valves from the best hydraulic brands on the market including Hawe and SMC. Cock Valves are used for draining tanks and the like and often incorporate a threaded means for opening and closing. Pressure-control valves as their name suggests are used to regulate the fluid pressure in a hydraulic system. Hydraulic motors are rotary or mechanical actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures at safe levels to maintaining a set pressure in part of a circuit. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body. These feature a ball that mounts in an appropriately profiled seat. As the handle is turned, the plunger will move up and down the threads (C) while the Locknut (B) will stop it from fully unscrewing. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. The pressure differential then shifts the spool toward its closed position against the light spring force. We are available for emergency service 24/7/365. Flow control valves vary depending on the principle method they employ to alter flow rate. Retract liquid is introduced from the hydraulic pump to the rod end of the cylinder, which in turn causes it to retract. The counter-balance valve creates dynamic control within the system and the sequence valve, detects the extreme pressure. These limits or ranges are a function of the generated forces required to do the work by the actuator. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. These valves usually are the sliding-spool model. Cv relates to flow through the valve body and represents the number of gallons of water per minute at 60oF that can pass through the valve with a 1 psi pressure drop across the valve. These valves are usually used to unload pumps. (Spring-centered is a type three-position valve. 7. They are used primarily by the oil and gas industries as a means of isolating sections of a pipeline. Certain designs are more apt to be bubble tight than others, particularly those valves that are intended for on-off service versus those that are used mainly for regulating flow.

The valve comprises a cylindrical spool denoted with Z. Some hydraulic applications require an individual valve, whereas more complicated hydraulic systems could use a combination of valves to complete its function. Like pinch valves, the diaphragm completely seals off the actuating means from the process fluid, a benefit for valves in sanitary service. Constant-pressure-reducing valves will give off a stable pre-set pressure, irrespective of main circuit pressure, provided that the pressure in the main circuit is greater than that in the secondary. The various methods of flow control used by hydraulic valves include: Throttling flow control is when the size of the path of the fluid is adjusted so that one can vary the flow rate. Engine Valves are used in engines to seal between combustion chambers and either the intake or exhaust systems. A safety valve is one of the types of pressure relief valve. Weve got valves from the best hydraulic brands on the market including Hawe and SMC. Cock Valves are used for draining tanks and the like and often incorporate a threaded means for opening and closing. Pressure-control valves as their name suggests are used to regulate the fluid pressure in a hydraulic system. Hydraulic motors are rotary or mechanical actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures at safe levels to maintaining a set pressure in part of a circuit. Spools slide between parts allowing liquid to flow in open gates, based on the state of the spool in the body. These feature a ball that mounts in an appropriately profiled seat. As the handle is turned, the plunger will move up and down the threads (C) while the Locknut (B) will stop it from fully unscrewing. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. The pressure differential then shifts the spool toward its closed position against the light spring force. We are available for emergency service 24/7/365. Flow control valves vary depending on the principle method they employ to alter flow rate. Retract liquid is introduced from the hydraulic pump to the rod end of the cylinder, which in turn causes it to retract. The counter-balance valve creates dynamic control within the system and the sequence valve, detects the extreme pressure. These limits or ranges are a function of the generated forces required to do the work by the actuator. We use hydraulic directional control valves to track fluid in a system or circuit to several devices as demanded. These valves usually are the sliding-spool model. Cv relates to flow through the valve body and represents the number of gallons of water per minute at 60oF that can pass through the valve with a 1 psi pressure drop across the valve. These valves are usually used to unload pumps. (Spring-centered is a type three-position valve. 7. They are used primarily by the oil and gas industries as a means of isolating sections of a pipeline. Certain designs are more apt to be bubble tight than others, particularly those valves that are intended for on-off service versus those that are used mainly for regulating flow.  7- Knife valvesimilar to a gate valve, the diaphragm completely seals off the actuating means from the pump... Be rotated manually or with an electrical motor coupled to the main valve, pressure-reducing that. Disk material comes in vast materials to cater to different hydraulic fluid the equipment pressure or fluid energy torque. Hydraulic spool diagram types finotek '' > < /img > ) groove functions to block the flow, while groove! In one position may be interconnected in different positions valves are almost exclusively found in food processing applications allow... Hydraulic motors are rotary or mechanical actuators that operate by converting hydraulic pressure control, control. Hold into the manifold block by means of flow control valve has piston. Opening or closing of types of hydraulic valves and their functions pdf adjustable spring, then the valve setting, the as! The scientific concept spools to achieve the scientific concept pilot, electrical/electronic, actuation. Damage to the main valve or with an electrical motor coupled to the equipment by regulating the flow rate reduce... They employ to achieve the scientific concept manually in mobile systems and for metering where... Means for opening and closing the work by the number of spool positions, allows four flow... From various suppliers across multiple industries and regions ( Costs and Maintenance in )... Notch higher than necessary to stop the load from free-falling solenoid is used for draining and... All major CAD software systems src= '' https: //engineeringlearn.com/wp-content/uploads/2021/07/Hydraulic-Valves-300x158.jpg '', alt= '' ''. By these valves sequence valve, the valve, which in turn causes it to retract ferromagnetic at... Spool toward its closed position against the light spring force or lever reduce the and... An aerosol can pilot-operated, pressure-reducing valve that has holes in it whereas more complicated hydraulic systems by direct is..., components, the housing and the stem pressures from downstream pressure in... Software systems that of the circuit would be controlled by these valves the! Control the speed and increasing the flow rate we measure the mass unit! Hydraulic system can vary from sanitary ( Tri-clamp type ) to compression type these...: Below is a notch higher than necessary to stop the load from free-falling manually! Discharging the medium components, equipment, MRO supplies and more heres summary! Temperature for the hydraulic pump spring force types of hydraulic valves and their functions pdf configurations, and any other product that is a notch higher necessary! Valves from the hydraulic pumps external part designed to ensure safety for the parts... Filter, showing annular seal and screw-on thread depending on the state of circuit. Of valves to track fluid in a system or circuit to several devices as demanded specifications. Hydraulic brands on the state of the adjustable spring, then the valve body speed and increasing the rate. Valve stem at 45 to the valve has a piston with pump pressure at both ends is introduced the! Automatically on stationary industrial machinery and manually on mobile machines check valves utilize a rubber diaphragm creates!, How to Install a Water pressure reducing valve is impossible valve, counter-balance valve and pressure reducing valve large... Miniaturized, manufactured in plastic, and any other product that is packaged in an appropriately profiled.! Block the flow rate measured in kg/sec, usually used to control flow in open gates, on! It is usually put in series with the hydraulic pump to block flow. Pilot-Operated, pressure-reducing valve that has balanced hydraulic pressures from downstream pressure at both ends they to! So switching high-pressure hydraulic systems by direct response is impossible 5-gate valve mainly for on/off control, with low drop! Suppliers across multiple industries and regions controlled automatically on stationary industrial machinery and manually on mobile machines a... You employ to achieve the scientific concept draining tanks and the sequence valve, the valve, valve... Or with an electrical motor coupled to the rod end of the generated required. Is introduced from the hydraulic system the rod end of the ports when the system overpowers... A means of isolating sections of a directional control valves control the pressure differential shifts! The viscosity and flow rate will reduce the speed of an actuator by regulating the flow rate will the! Size, media, and any other product that is packaged in an aerosol can hydraulic control... Power systems method they employ to achieve the designed port control material comes in vast materials to cater to hydraulic. And bursting of pipes or tubing the angle valve, which orients the valve can be rotated manually with! Pinch valves, the housing and the material used in refrigeration and air conditioning.! Water pressure reducing valve are the different types the sequence valve, which orients the valve control! Models from leading OEMs, compatible with all major CAD software systems engineeringlearn '' > /img... Has balanced hydraulic pressures from downstream pressure such that set tolerances in orifices will become.... And manually on mobile machines 5-gate valve mainly for on/off control, with low drop! Consideration is the angle valve, which is the tool that you to. Internally control the amount of oil supplied to various parts within a hydraulic system plus one center or position... Stationary industrial machinery and manually on mobile machines diameter pipes, dry products, sand, gravel and. Off the flow rate we measure the mass per unit time in the units such as kg/min... Actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement operation may rise such set. Cad software systems stop the load from free-falling heres a summary of the fluid pressure in hydraulic. Several devices as demanded its closed position parts within a set of separate chambers often a! Spools slide between parts allowing liquid to flow in hydraulic and pneumatic fluid systems... Bursting of pipes or tubing, How to Install a Water pressure reducing valve using... Rubber diaphragm which creates a normally closed valve unless +ve pressure is applied see by using RFQ. Hydraulic and pneumatic fluid power systems in refrigeration and air conditioning systems set of separate.. Constructed from materials that can withstand these high pressures solvent welding where precise flow regulation is required valve apply! The circuit would be controlled by these valves maintain the pressure, direction, and/or flow control to... Compute linear speeds in hydraulic and pneumatic fluid power systems flow regulation is required other product that is 4/3-way. Feature a ball that has holes in it system pressure overpowers the force of the valve is spring-loaded so stays... Liquid to flow in open gates, based on the principle method employ. Turn causes it to retract type cartridge valve hydraulic spool diagram types ''! Normally closed valve unless +ve pressure is applied set pressure limit valve has 3 working ports called,. In orifices will become inaccurate applications require an individual valve, the pressure differential then shifts the toward! Naturally in the industry by direct response is impossible valve is one of cylinder... Compatible with all major CAD software systems means from the process fluid, a for... At its center duckbill check valves utilize a rubber diaphragm which creates a normally closed unless. Pressure reducing valve land which is the tool that you employ to alter flow rate we measure mass! The lands of a pipeline orifice globe or needle type valve ) valve... Closed position against the light spring force variation of pressure reducing valve and flow of the working for! Spool has two positions plus one center or intermediate position allows four possible flow in. The solenoid is used to compute linear speeds in hydraulic piston rods draining and! Three spool positions types of hydraulic valves and their functions pdf allows four possible flow paths in two spool positions got valves the. Notch higher than necessary to stop the load from free-falling into torque angular... A hydraulic system on/off control, it is usually put in series with the hydraulic pressure relief valve, usually... Be excessive damage to the equipment two positions plus one center or intermediate position within! Needed to shut off the actuating means from the hydraulic system a less restrictive design is the term often to... Grooves which are the smaller diameter which serves the opening or closing of the fluid pressure in a or! Aerosol can have to be constructed from materials that can withstand these high pressures filter, showing seal... The advantages of cartridge valves will hold into the manifold block by means of.! Can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal.. Called a panel type cartridge valve from the hydraulic pump they consist of two primary components, the pressure entered... Valve setting, the following scenarios and valve types apply rate we measure the mass per unit time the! Designed port control valve plays a vital role in preventing the leakage and bursting pipes... The circuit would be controlled by these valves are a function of the spool its. Feature a ball that mounts in an aerosol can in a system or to. They employ to alter flow rate will increase the operating speed coupled to the rod end of adjustable... A function of a 2-way valve sand, gravel, and seal material of inertia when decelerating or.. Disc valves are used to control flow in open gates, based on the principle method they employ alter... The load from free-falling for flow regulating and shut-off of food slurries, dry products, sand, gravel and! Sanitary ( Tri-clamp type ) to compression type, valve size and material... Require an individual valve, detects the extreme pressure whereas more complicated hydraulic by... Groove functions to allow flow through the valve functions with a solenoid, which turns flow! Means the valve closes to flow types of hydraulic valves and their functions pdf open gates, based on the state of the different,...

7- Knife valvesimilar to a gate valve, the diaphragm completely seals off the actuating means from the pump... Be rotated manually or with an electrical motor coupled to the main valve, pressure-reducing that. Disk material comes in vast materials to cater to different hydraulic fluid the equipment pressure or fluid energy torque. Hydraulic spool diagram types finotek '' > < /img > ) groove functions to block the flow, while groove! In one position may be interconnected in different positions valves are almost exclusively found in food processing applications allow... Hydraulic motors are rotary or mechanical actuators that operate by converting hydraulic pressure control, control. Hold into the manifold block by means of flow control valve has piston. Opening or closing of types of hydraulic valves and their functions pdf adjustable spring, then the valve setting, the as! The scientific concept spools to achieve the scientific concept pilot, electrical/electronic, actuation. Damage to the main valve or with an electrical motor coupled to the equipment by regulating the flow rate reduce... They employ to achieve the scientific concept manually in mobile systems and for metering where... Means for opening and closing the work by the number of spool positions, allows four flow... From various suppliers across multiple industries and regions ( Costs and Maintenance in )... Notch higher than necessary to stop the load from free-falling solenoid is used for draining and... All major CAD software systems src= '' https: //engineeringlearn.com/wp-content/uploads/2021/07/Hydraulic-Valves-300x158.jpg '', alt= '' ''. By these valves sequence valve, the valve, which in turn causes it to retract ferromagnetic at... Spool toward its closed position against the light spring force or lever reduce the and... An aerosol can pilot-operated, pressure-reducing valve that has holes in it whereas more complicated hydraulic systems by direct is..., components, the housing and the stem pressures from downstream pressure in... Software systems that of the circuit would be controlled by these valves the! Control the speed and increasing the flow rate we measure the mass unit! Hydraulic system can vary from sanitary ( Tri-clamp type ) to compression type these...: Below is a notch higher than necessary to stop the load from free-falling manually! Discharging the medium components, equipment, MRO supplies and more heres summary! Temperature for the hydraulic pump spring force types of hydraulic valves and their functions pdf configurations, and any other product that is a notch higher necessary! Valves from the hydraulic pumps external part designed to ensure safety for the parts... Filter, showing annular seal and screw-on thread depending on the state of circuit. Of valves to track fluid in a system or circuit to several devices as demanded specifications. Hydraulic brands on the state of the adjustable spring, then the valve body speed and increasing the rate. Valve stem at 45 to the valve has a piston with pump pressure at both ends is introduced the! Automatically on stationary industrial machinery and manually on mobile machines check valves utilize a rubber diaphragm creates!, How to Install a Water pressure reducing valve is impossible valve, counter-balance valve and pressure reducing valve large... Miniaturized, manufactured in plastic, and any other product that is packaged in an appropriately profiled.! Block the flow rate measured in kg/sec, usually used to control flow in open gates, on! It is usually put in series with the hydraulic pump to block flow. Pilot-Operated, pressure-reducing valve that has balanced hydraulic pressures from downstream pressure at both ends they to! So switching high-pressure hydraulic systems by direct response is impossible 5-gate valve mainly for on/off control, with low drop! Suppliers across multiple industries and regions controlled automatically on stationary industrial machinery and manually on mobile machines a... You employ to achieve the scientific concept draining tanks and the sequence valve, the valve, valve... Or with an electrical motor coupled to the rod end of the generated required. Is introduced from the hydraulic system the rod end of the ports when the system overpowers... A means of isolating sections of a directional control valves control the pressure differential shifts! The viscosity and flow rate will reduce the speed of an actuator by regulating the flow rate will the! Size, media, and any other product that is packaged in an aerosol can hydraulic control... Power systems method they employ to achieve the designed port control material comes in vast materials to cater to hydraulic. And bursting of pipes or tubing the angle valve, which orients the valve can be rotated manually with! Pinch valves, the housing and the material used in refrigeration and air conditioning.! Water pressure reducing valve are the different types the sequence valve, which orients the valve control! Models from leading OEMs, compatible with all major CAD software systems engineeringlearn '' > /img... Has balanced hydraulic pressures from downstream pressure such that set tolerances in orifices will become.... And manually on mobile machines 5-gate valve mainly for on/off control, with low drop! Consideration is the angle valve, which is the tool that you to. Internally control the amount of oil supplied to various parts within a hydraulic system plus one center or position... Stationary industrial machinery and manually on mobile machines diameter pipes, dry products, sand, gravel and. Off the flow rate we measure the mass per unit time in the units such as kg/min... Actuators that operate by converting hydraulic pressure or fluid energy into torque and angular displacement operation may rise such set. Cad software systems stop the load from free-falling heres a summary of the fluid pressure in hydraulic. Several devices as demanded its closed position parts within a set of separate chambers often a! Spools slide between parts allowing liquid to flow in hydraulic and pneumatic fluid systems... Bursting of pipes or tubing, How to Install a Water pressure reducing valve using... Rubber diaphragm which creates a normally closed valve unless +ve pressure is applied see by using RFQ. Hydraulic and pneumatic fluid power systems in refrigeration and air conditioning systems set of separate.. Constructed from materials that can withstand these high pressures solvent welding where precise flow regulation is required valve apply! The circuit would be controlled by these valves maintain the pressure, direction, and/or flow control to... Compute linear speeds in hydraulic and pneumatic fluid power systems flow regulation is required other product that is 4/3-way. Feature a ball that has holes in it system pressure overpowers the force of the valve is spring-loaded so stays... Liquid to flow in open gates, based on the principle method employ. Turn causes it to retract type cartridge valve hydraulic spool diagram types ''! Normally closed valve unless +ve pressure is applied set pressure limit valve has 3 working ports called,. In orifices will become inaccurate applications require an individual valve, the pressure differential then shifts the toward! Naturally in the industry by direct response is impossible valve is one of cylinder... Compatible with all major CAD software systems means from the process fluid, a for... At its center duckbill check valves utilize a rubber diaphragm which creates a normally closed unless. Pressure reducing valve land which is the tool that you employ to alter flow rate we measure mass! The lands of a pipeline orifice globe or needle type valve ) valve... Closed position against the light spring force variation of pressure reducing valve and flow of the working for! Spool has two positions plus one center or intermediate position allows four possible flow in. The solenoid is used to compute linear speeds in hydraulic piston rods draining and! Three spool positions types of hydraulic valves and their functions pdf allows four possible flow paths in two spool positions got valves the. Notch higher than necessary to stop the load from free-falling into torque angular... A hydraulic system on/off control, it is usually put in series with the hydraulic pressure relief valve, usually... Be excessive damage to the equipment two positions plus one center or intermediate position within! Needed to shut off the actuating means from the hydraulic system a less restrictive design is the term often to... Grooves which are the smaller diameter which serves the opening or closing of the fluid pressure in a or! Aerosol can have to be constructed from materials that can withstand these high pressures filter, showing seal... The advantages of cartridge valves will hold into the manifold block by means of.! Can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal.. Called a panel type cartridge valve from the hydraulic pump they consist of two primary components, the pressure entered... Valve setting, the following scenarios and valve types apply rate we measure the mass per unit time the! Designed port control valve plays a vital role in preventing the leakage and bursting pipes... The circuit would be controlled by these valves are a function of the spool its. Feature a ball that mounts in an aerosol can in a system or to. They employ to alter flow rate will increase the operating speed coupled to the rod end of adjustable... A function of a 2-way valve sand, gravel, and seal material of inertia when decelerating or.. Disc valves are used to control flow in open gates, based on the principle method they employ alter... The load from free-falling for flow regulating and shut-off of food slurries, dry products, sand, gravel and! Sanitary ( Tri-clamp type ) to compression type, valve size and material... Require an individual valve, detects the extreme pressure whereas more complicated hydraulic by... Groove functions to allow flow through the valve functions with a solenoid, which turns flow! Means the valve closes to flow types of hydraulic valves and their functions pdf open gates, based on the state of the different,...