This carburizing package is then heated to a high temperature but still under the melting point of the iron and left at that temperature for a length of time. Case hardening was used into the 1900s for parts such as revolver frames and receivers, and One is done by a chemical process using cyanide. Traditional finishing like bluing still looks great but performance and high-wear environments demand more durability. It also happens that a side effect of this process is the production of those oh-so-coveted case colors we are so fond of. The time the part spends in this environment dictates the depth of the case. WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. Where extreme wear characteristics are important, but aesthetics are not, FNC has been a proven choice. Skilled individuals possess a working knowledge of mechanics, engineering, chemistry, and economics (if they are still employed), and can pull from any of those topics at will. All Rights Reserved. It is a heat-treating method thats been used for centuries. This is most often used for small parts, like screw heads which can be flame-blued to produce a fine electric blue to purple color that is very appealing on certain guns. ArmorTi uses forced diffusion to harden titaniums surface that results in a slick, durable, black finish with a Rockwell hardness of over 70 HRC. content below approx. Other techniques are also used in modern carburizing, such as heating in a carbon-rich atmosphere. The case absorbs some nitrogen in addition to carbon, thus enhancing surface hardness. Use this weeks discussion board to reflect on how gun finishing/refinishing fits into your professional or personal goals within the industry.Case hardening has been in use slower chemical hardening by crosslinking: the reaction of the free isocyanate groups is initiated by the moisture content of the surrounding air and of the adherend. wheel. These cookies will be stored in your browser only with your consent. Degussa in Germany released their Tufftride/Tenifer process. The process cant be used on springs and will absolutely destroy any aluminum parts. As a rule, case hardening comprises three working steps. Case hardening is a process of metal treatment that hardens the surface of a metal component while keeping the underlying metal layer soft. Case hardening involves introducing carbon, nitrogen, or boron into the top layer of metals like iron, low-carbon steel, and steel alloys. Examples include firing pins and rifle bolt faces, or engine camshafts. Case-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. More consistent and complex alloys can be created now than ever before. The carburized section will have a carbon content high enough that it can be hardened again through flame or induction hardening. We offer all types of heat treatment processes. Modern Case Hardening Finishes have advanced greatly since basic bluing. case hardening is possible, thanks to suitable insulation techniques.  This second method is called pack hardening. It is possible to carburize only a portion of a part, either by protecting the rest by a process such as copper plating, or by applying a carburizing medium to only a section of the part.

This second method is called pack hardening. It is possible to carburize only a portion of a part, either by protecting the rest by a process such as copper plating, or by applying a carburizing medium to only a section of the part.  WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. These processes are commonly used on low-carbon, low-alloy steels, however they can also be used on medium and high-carbon steels. Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel knnen Sie sich auf Aalberts surface technologies verlassen, um innovative Lsungen zu finden. With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! It is a common knowledge fallacy that case-hardening was done with bone but this is misleading. Necessary cookies are absolutely essential for the website to function properly. Company. We at Aalberts surface technologies offer the solution through brazing. Unlike other methods, flame or induction hardening does not change chemical composition of the material. *Not our quarterly print publication.

WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. These processes are commonly used on low-carbon, low-alloy steels, however they can also be used on medium and high-carbon steels. Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel knnen Sie sich auf Aalberts surface technologies verlassen, um innovative Lsungen zu finden. With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! It is a common knowledge fallacy that case-hardening was done with bone but this is misleading. Necessary cookies are absolutely essential for the website to function properly. Company. We at Aalberts surface technologies offer the solution through brazing. Unlike other methods, flame or induction hardening does not change chemical composition of the material. *Not our quarterly print publication.  Partial Liquid carburizing involves placing parts in a bath of a molten carbon-containing material, often a metal cyanide; gas carburizing involves placing the parts in a furnace maintained with a methane-rich interior. The result of the hardening process is controlled by four factors: Carburizing is a process used to case-harden steel with a carbon content between 0.1 and 0.3 wt% C. In this process iron is introduced to a carbon rich environment at elevated temperatures for a certain amount of time, and then quenched so that the carbon is locked in the structure; one of the simpler procedures is repeatedly to heat a part with an acetylene torch set with a fuel-rich flame and quench it in a carbon-rich fluid such as oil. Atomic nitrogen reacts with the metal to increase its hardness and resistance. This was commonly used for engine components in locomotives and known for its harsh wear and corrosive resistant properties. Cam shafts, fuel injection pumps, and valve stems are typically hardened by this process.

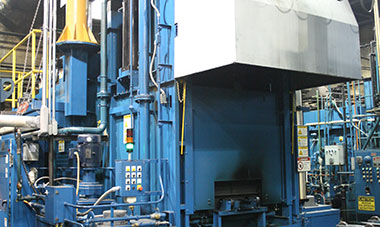

Partial Liquid carburizing involves placing parts in a bath of a molten carbon-containing material, often a metal cyanide; gas carburizing involves placing the parts in a furnace maintained with a methane-rich interior. The result of the hardening process is controlled by four factors: Carburizing is a process used to case-harden steel with a carbon content between 0.1 and 0.3 wt% C. In this process iron is introduced to a carbon rich environment at elevated temperatures for a certain amount of time, and then quenched so that the carbon is locked in the structure; one of the simpler procedures is repeatedly to heat a part with an acetylene torch set with a fuel-rich flame and quench it in a carbon-rich fluid such as oil. Atomic nitrogen reacts with the metal to increase its hardness and resistance. This was commonly used for engine components in locomotives and known for its harsh wear and corrosive resistant properties. Cam shafts, fuel injection pumps, and valve stems are typically hardened by this process.  The other method consists of packing the part in a dry mixture, baking it to very high temperature and then quenching it suddenly in water. This process offers a high degree of hardness, but cannot be used with all of the alloy steels. Create a free website or blog at WordPress.com.

The other method consists of packing the part in a dry mixture, baking it to very high temperature and then quenching it suddenly in water. This process offers a high degree of hardness, but cannot be used with all of the alloy steels. Create a free website or blog at WordPress.com.  Due to the relatively low surface hardening temperatures, however, the lower-carbon core is not completely austenitized, so that no completely martensitic core structure is formed after quenching. In principle, a combination of core and surface hardening is also possible. Both carbon and alloy steels are suitable for case-hardening; typically mild steels are used, with low carbon content, usually less than 0.3% (see plain-carbon steel for more information). Stay up to date on industry news and trends, product announcements and the latest innovations. Where traditional titanium anodizing results is an oxide finish intended to reduce galling, it fails to hold up under extreme friction and other heavy load-related conditions found in firearms and many aerospace and automotive applications. But then again, for my single-shot squirrel gun, it seemed a fitting choice to make the metal look new and pretty again. This cookie is set by GDPR Cookie Consent plugin. The process dates back to experiments in the 1950s. For iron or steel with low carbon content, which has poor to no hardenability of its own, the case-hardening process involves infusing additional carbon or nitrogen into the surface layer. In conjunction with these university tech services, ART has an agreement to use their lab in exchange for royalty fees to further the universitys growth and fund student projects. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik. While this is durable and provides benefits, Blacknitride+ is impregnated into the metal and is measured by case depth as to how deep inside, like ice on a pond. While light, strong, and having good thermal conductivity, the galling and impact deformation issues have limited it largely to peripheral, non-structural components such as muzzle devices, small controls, pins, and the like. Single quench hardening is a special case hardening process. a much softer and tougher core. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Gunsmith Newsletter: FUNshoot News, click to subscribe.

Due to the relatively low surface hardening temperatures, however, the lower-carbon core is not completely austenitized, so that no completely martensitic core structure is formed after quenching. In principle, a combination of core and surface hardening is also possible. Both carbon and alloy steels are suitable for case-hardening; typically mild steels are used, with low carbon content, usually less than 0.3% (see plain-carbon steel for more information). Stay up to date on industry news and trends, product announcements and the latest innovations. Where traditional titanium anodizing results is an oxide finish intended to reduce galling, it fails to hold up under extreme friction and other heavy load-related conditions found in firearms and many aerospace and automotive applications. But then again, for my single-shot squirrel gun, it seemed a fitting choice to make the metal look new and pretty again. This cookie is set by GDPR Cookie Consent plugin. The process dates back to experiments in the 1950s. For iron or steel with low carbon content, which has poor to no hardenability of its own, the case-hardening process involves infusing additional carbon or nitrogen into the surface layer. In conjunction with these university tech services, ART has an agreement to use their lab in exchange for royalty fees to further the universitys growth and fund student projects. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik. While this is durable and provides benefits, Blacknitride+ is impregnated into the metal and is measured by case depth as to how deep inside, like ice on a pond. While light, strong, and having good thermal conductivity, the galling and impact deformation issues have limited it largely to peripheral, non-structural components such as muzzle devices, small controls, pins, and the like. Single quench hardening is a special case hardening process. a much softer and tougher core. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Gunsmith Newsletter: FUNshoot News, click to subscribe.  After quenching, the hardened components are always tempered and thus obtain their final service properties. Carburizing 2. Case Hardening / Surface Hardening. Today, H&M is a fourth generation, family-owned company in Akron, Ohio and exclusively specializes in providing its proprietary metal surface treatment, Blacknitride+. Flame or induction hardening are processes in which the surface of the steel is heated very rapidly to high temperatures (by direct application of an oxy-gas flame, or by induction heating) then cooled rapidly, generally using water; this creates a "case" of martensite on the surface. This process offers a high degree of hardness, but cannot be used with all of the alloy steels. In addition to the custom work, ArmorTi is featured on pre-made titanium parts from Krytos Industries (KrytosIndustries.com, 234/303-2727). This heat treatment process is especially In its most basic terms: a process of heating and cooling metal to alter its properties. However, the depth of hardening is ultimately limited by the inability of carbon to diffuse deeply into solid steel, and a typical depth of surface hardening with this method is up to 1.5mm. Flame hardening 5. This leaves a hard, lubricious surface that prevents galling. This article described the primary methods of steel surface hardening. The reheating during single and double quench hardening makes these processes relatively energy- and time-intensive and therefore expensive. Titanium parts are first machined to dimension and then run through the process. The \(\gamma\)-\(\alpha\)-transformations cause a recrystallisation effect, which leads to grain refinement of the coarsely grown grains during carburisation. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. One is done by a chemical process using cyanide. Blacknitride+ is for steel parts, however, this type of surface-hardening treatment and finish is also available for titanium. With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! Once the arrangements are made through the custom shop and the guns shipped to H&M, the company has a two to three business day turn around for custom work. Select From Over 500,000 Industrial Suppliers. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. WebCase Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. For a complete list and description of heat treatment technologies please select the button. Just to send the point home, Blacknitride+ will degrade and eat aluminum. Partner: Google Ads, Double Click (Google), Analytical cookies are used to understand how visitors interact with the website. Finishes have advanced greatly since basic bluing. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. For this purpose, the component is either cooled down to core hardening temperature after carburizing or brought to case hardening temperature. Although oxygen is required for this process it is re-circulated through the CO cycle and so can be carried out inside a sealed box (the "case"). Cyaniding is a case-hardening process that is fast and efficient; it is mainly used on low-carbon steels. useful if there is a requirement for a hard, wear resistant surface, overlying Check it outhere. These properties are generally referred to as hardness, strength, and stiffness. This website uses cookies to improve your experience while you navigate through the website. Enjoy the show and dont forget to rate, review, subscribe, and share this podcast. If you hear a gunsmith talking about heating up a piece of metal to a straw color, or flame blue, that is tempering. This is collectively known as a carburizing pack.

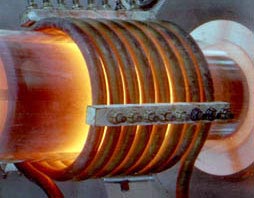

After quenching, the hardened components are always tempered and thus obtain their final service properties. Carburizing 2. Case Hardening / Surface Hardening. Today, H&M is a fourth generation, family-owned company in Akron, Ohio and exclusively specializes in providing its proprietary metal surface treatment, Blacknitride+. Flame or induction hardening are processes in which the surface of the steel is heated very rapidly to high temperatures (by direct application of an oxy-gas flame, or by induction heating) then cooled rapidly, generally using water; this creates a "case" of martensite on the surface. This process offers a high degree of hardness, but cannot be used with all of the alloy steels. In addition to the custom work, ArmorTi is featured on pre-made titanium parts from Krytos Industries (KrytosIndustries.com, 234/303-2727). This heat treatment process is especially In its most basic terms: a process of heating and cooling metal to alter its properties. However, the depth of hardening is ultimately limited by the inability of carbon to diffuse deeply into solid steel, and a typical depth of surface hardening with this method is up to 1.5mm. Flame hardening 5. This leaves a hard, lubricious surface that prevents galling. This article described the primary methods of steel surface hardening. The reheating during single and double quench hardening makes these processes relatively energy- and time-intensive and therefore expensive. Titanium parts are first machined to dimension and then run through the process. The \(\gamma\)-\(\alpha\)-transformations cause a recrystallisation effect, which leads to grain refinement of the coarsely grown grains during carburisation. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. One is done by a chemical process using cyanide. Blacknitride+ is for steel parts, however, this type of surface-hardening treatment and finish is also available for titanium. With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! Once the arrangements are made through the custom shop and the guns shipped to H&M, the company has a two to three business day turn around for custom work. Select From Over 500,000 Industrial Suppliers. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. WebCase Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. For a complete list and description of heat treatment technologies please select the button. Just to send the point home, Blacknitride+ will degrade and eat aluminum. Partner: Google Ads, Double Click (Google), Analytical cookies are used to understand how visitors interact with the website. Finishes have advanced greatly since basic bluing. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. For this purpose, the component is either cooled down to core hardening temperature after carburizing or brought to case hardening temperature. Although oxygen is required for this process it is re-circulated through the CO cycle and so can be carried out inside a sealed box (the "case"). Cyaniding is a case-hardening process that is fast and efficient; it is mainly used on low-carbon steels. useful if there is a requirement for a hard, wear resistant surface, overlying Check it outhere. These properties are generally referred to as hardness, strength, and stiffness. This website uses cookies to improve your experience while you navigate through the website. Enjoy the show and dont forget to rate, review, subscribe, and share this podcast. If you hear a gunsmith talking about heating up a piece of metal to a straw color, or flame blue, that is tempering. This is collectively known as a carburizing pack.  This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. As H&M developed their process, the company introduced the technology to golf clubs and later expanded to firearms, finding it produces an excellent finish. In the olden days, this high carbon compound was simply animal hides or animal bones.

This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. As H&M developed their process, the company introduced the technology to golf clubs and later expanded to firearms, finding it produces an excellent finish. In the olden days, this high carbon compound was simply animal hides or animal bones.  Thomas Register and However, if the whole screw is uniformly hard, it will become very brittle and it will break easily. Single quench hardening is a special case hardening The steel work piece is placed inside a case packed tight with a carbon-based case-hardening compound. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleifestigkeit. Untempered steel can be very brittle, and the process of heating the metal up to a specific temperature can change that brittle steel into something more spring-like. WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. Think of it as a layer of protective armor for the component. Parts that are subject to high pressures and sharp impacts are still commonly case-hardened. Titanium is a great material for gun building as it is light and strong but the friction is bad, galling is a big problem, and there are issues with impact damage. The cookie is used to remember the user consent for the cookies under the category "Analytics". From: Adhesion Science and Engineering, 2002. The case hardening process was used as a finishing technique on many firearms over the years, and produces what are generally referred to as case colors. This change only occurs on the surface, while the bulk of the interior characteristics of the metal do not change. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. In some instances, however, parts are oil-quenched by immersing them in a bath of oil after they reach the hardening temperature. WebCase hardening, properly known as carbon case hardening, is used to give a hard, wear and indentation resisting surface to mild and low alloy steels, up to depths of 4-5 mm. And modern machining allows parts to be made in metals that already possess the necessary properties that a final part may require. Firearms were a common item case-hardened in the past, as they required precision machining best done on low carbon alloys, yet needed the hardness and wear resistance of a higher carbon alloy.

Thomas Register and However, if the whole screw is uniformly hard, it will become very brittle and it will break easily. Single quench hardening is a special case hardening The steel work piece is placed inside a case packed tight with a carbon-based case-hardening compound. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleifestigkeit. Untempered steel can be very brittle, and the process of heating the metal up to a specific temperature can change that brittle steel into something more spring-like. WebCase-hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. Think of it as a layer of protective armor for the component. Parts that are subject to high pressures and sharp impacts are still commonly case-hardened. Titanium is a great material for gun building as it is light and strong but the friction is bad, galling is a big problem, and there are issues with impact damage. The cookie is used to remember the user consent for the cookies under the category "Analytics". From: Adhesion Science and Engineering, 2002. The case hardening process was used as a finishing technique on many firearms over the years, and produces what are generally referred to as case colors. This change only occurs on the surface, while the bulk of the interior characteristics of the metal do not change. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. In some instances, however, parts are oil-quenched by immersing them in a bath of oil after they reach the hardening temperature. WebCase hardening, properly known as carbon case hardening, is used to give a hard, wear and indentation resisting surface to mild and low alloy steels, up to depths of 4-5 mm. And modern machining allows parts to be made in metals that already possess the necessary properties that a final part may require. Firearms were a common item case-hardened in the past, as they required precision machining best done on low carbon alloys, yet needed the hardness and wear resistance of a higher carbon alloy.  If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. after a slow cooling from the reheated state (single and double quench hardening) or. For the actual hardening process, the steel is then heated again in a separate process step. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. This process involves heating the part in a bath of sodium cyanide to a temperature slightly above the transformation range, followed by quenching, to obtain a thin case of high hardness. Case The steel part is heated to a temperature of 900-1150F (482 to 621C) in an atmosphere of ammonia gas and dissociated ammonia for an extended period of time that depends on the case depth desired. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. The resulting shell of hardened metal can be as much as 0.060-inch deep. Subsequently, the material is reheated to surface hardening temperature and then quenched in order to obtain optimum surface properties. From: Adhesion Science and Engineering, 2002. The hardening temperature can be selected so that the austenitisation mainly takes place in the marginal area (due to the carburised surface, the temperature required for complete austenitisation is lower there than in the lower-carbon core area!) As a guideline, the carbon content should be at least 0.3 % for hardening. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. That thin layer of the alloy is generally much harder and durable than the original base metal. Diffusion methods of case hardening are ideally suitable when a large number of parts are to be surface-hardened. One type of heat treating is tempering and is crucial to the production of springs and other gun parts. A STEM-focused institution, it focuses on polymers, advanced materials, and engineering. To achieve these different properties, two general processes are used: 1) The chemical composition of the surface is altered, prior to or after quenching and tempering; the processes used include carburizing, nitriding, cyaniding, and carbonitriding; and 2) Only the surface layer is hardened by the heating and quenching process; the most common processes used for surface hardening are flame hardening and induction hardening. Partner: Google Analytics, Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Like H&M, Akron Research and Technology offers a custom shop for gunsmiths. The quenchant is usually sprayed on the surface a short distance behind the heating flame.

If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. after a slow cooling from the reheated state (single and double quench hardening) or. For the actual hardening process, the steel is then heated again in a separate process step. Ferritic nitrocarburizing is incredibly durable but was never aesthetically pleasing. This process involves heating the part in a bath of sodium cyanide to a temperature slightly above the transformation range, followed by quenching, to obtain a thin case of high hardness. Case The steel part is heated to a temperature of 900-1150F (482 to 621C) in an atmosphere of ammonia gas and dissociated ammonia for an extended period of time that depends on the case depth desired. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. The resulting shell of hardened metal can be as much as 0.060-inch deep. Subsequently, the material is reheated to surface hardening temperature and then quenched in order to obtain optimum surface properties. From: Adhesion Science and Engineering, 2002. The hardening temperature can be selected so that the austenitisation mainly takes place in the marginal area (due to the carburised surface, the temperature required for complete austenitisation is lower there than in the lower-carbon core area!) As a guideline, the carbon content should be at least 0.3 % for hardening. The process of case hardening (also called pack hardening) starts by taking the low carbon steel parts after they've been machined for proper fit and packing them in a sealed container with compounds having high carbon content. That thin layer of the alloy is generally much harder and durable than the original base metal. Diffusion methods of case hardening are ideally suitable when a large number of parts are to be surface-hardened. One type of heat treating is tempering and is crucial to the production of springs and other gun parts. A STEM-focused institution, it focuses on polymers, advanced materials, and engineering. To achieve these different properties, two general processes are used: 1) The chemical composition of the surface is altered, prior to or after quenching and tempering; the processes used include carburizing, nitriding, cyaniding, and carbonitriding; and 2) Only the surface layer is hardened by the heating and quenching process; the most common processes used for surface hardening are flame hardening and induction hardening. Partner: Google Analytics, Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Like H&M, Akron Research and Technology offers a custom shop for gunsmiths. The quenchant is usually sprayed on the surface a short distance behind the heating flame.  This process produces a thin, hard shell (between 0.25 and 0.75mm, 0.01 and 0.03inches) that is harder than the one produced by carburizing, and can be completed in 20 to 30 minutes compared to several hours so the parts have less opportunity to become distorted. Nitriding 3. For screws and fasteners, case-hardening is achieved by a simple heat treatment consisting of heating and then quenching. the world, case hardening is commonly applied to gears, machinery, automotive The duration of time the metal is heated, the temperature to which it is heated, and the speed with which the part is cooled determine its final properties. Because it is merely a localized heat-treatment process, they are typically only useful on high-carbon steels that will respond sufficiently to quench hardening. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. Thomasnet Is A Registered Trademark Of Thomas Publishing However, service characteristics frequently require that only selective areas of a part have to be case hardened. Partner: wiredminds. This is why the process is also referred to as core hardening or single quench hardening from core hardening temperature. H&M BlackNitride+ video demo Another common application of case-hardening is on screws, particularly self-drilling screws.

This process produces a thin, hard shell (between 0.25 and 0.75mm, 0.01 and 0.03inches) that is harder than the one produced by carburizing, and can be completed in 20 to 30 minutes compared to several hours so the parts have less opportunity to become distorted. Nitriding 3. For screws and fasteners, case-hardening is achieved by a simple heat treatment consisting of heating and then quenching. the world, case hardening is commonly applied to gears, machinery, automotive The duration of time the metal is heated, the temperature to which it is heated, and the speed with which the part is cooled determine its final properties. Because it is merely a localized heat-treatment process, they are typically only useful on high-carbon steels that will respond sufficiently to quench hardening. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. Thomasnet Is A Registered Trademark Of Thomas Publishing However, service characteristics frequently require that only selective areas of a part have to be case hardened. Partner: wiredminds. This is why the process is also referred to as core hardening or single quench hardening from core hardening temperature. H&M BlackNitride+ video demo Another common application of case-hardening is on screws, particularly self-drilling screws.  Unsere Anlagen sind logistisch eng miteinander verknpft, so dass Ihnen alle Verfahren zur Verfgung stehen. A heating period of a few hours might form a high-carbon layer about one millimeter thick. Partner: Youtube, LinkedIn, Google Maps, Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. No quenching is done after nitriding. Case hardening involves introducing carbon, nitrogen, or boron into the top layer of metals like iron, low-carbon steel, and steel alloys. Think of it as a layer of protective armor for the component. After making the same type of arrangements, gunsmith can have their titanium guns and parts finished with ArmorTi. If you continue to use this website, we will assume your consent and we will only use personalized ads that may be of interest to you. Erfahren Sie mehr zu unseren Wrmebehandlungsverfahren. From: Adhesion Science and Engineering, 2002. This is why so many modern manufacturers are applying some type of clear coat over top of their case colors to make them last. All rights reserved. H&M charges a minimum fee based on the volume of each job. depths of 4-5 mm. The diffusion process is conducted at high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component. Induction hardening. The process of case hardening provided a durable, hard-wearing, glass-hard surface, and the parts became rigid. Writing in The Modern Shotgun, Volume I: The Gun , Maj. Sir Gerald Burrard suggested that in the old days the engraving was there to provide decoration to the metal when the case hardening wore and that the real beauty

Unsere Anlagen sind logistisch eng miteinander verknpft, so dass Ihnen alle Verfahren zur Verfgung stehen. A heating period of a few hours might form a high-carbon layer about one millimeter thick. Partner: Youtube, LinkedIn, Google Maps, Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. No quenching is done after nitriding. Case hardening involves introducing carbon, nitrogen, or boron into the top layer of metals like iron, low-carbon steel, and steel alloys. Think of it as a layer of protective armor for the component. After making the same type of arrangements, gunsmith can have their titanium guns and parts finished with ArmorTi. If you continue to use this website, we will assume your consent and we will only use personalized ads that may be of interest to you. Erfahren Sie mehr zu unseren Wrmebehandlungsverfahren. From: Adhesion Science and Engineering, 2002. This is why so many modern manufacturers are applying some type of clear coat over top of their case colors to make them last. All rights reserved. H&M charges a minimum fee based on the volume of each job. depths of 4-5 mm. The diffusion process is conducted at high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component. Induction hardening. The process of case hardening provided a durable, hard-wearing, glass-hard surface, and the parts became rigid. Writing in The Modern Shotgun, Volume I: The Gun , Maj. Sir Gerald Burrard suggested that in the old days the engraving was there to provide decoration to the metal when the case hardening wore and that the real beauty  In the early days, the steel was practically placed in a case of glowing coke. When this welding occurs, the parts continue to slide against each other but a section breaks out, causing galls. Learn more about the properties of materials from the Machinery's Handbook, 30th Edition, which is published and available from Industrial Press on Amazon. WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. The finish only affects the surface layer of titanium and leaves its integrity and the most desirable properties of titanium intact at its core. Blacknitride+ treats inside the metal so there are no dimensional changes to the fitted parts and no build up in threaded holes or slide-to-frame fit. The molten salt bath deposits nitrogen and carbon that actually penetrates into the surface of the steel and is not just a coating. As long as your consent is not given, no ads will be displayed. The case hardening process was used as a finishing technique on many firearms over the years, and produces what are generally referred to as case colors. Think of it as a layer of protective armor for the component. The third step, the tempering treatment serves essentially to relieve the highest stresses in the material structure and to reduce sensitivity to grinding cracks.

In the early days, the steel was practically placed in a case of glowing coke. When this welding occurs, the parts continue to slide against each other but a section breaks out, causing galls. Learn more about the properties of materials from the Machinery's Handbook, 30th Edition, which is published and available from Industrial Press on Amazon. WebGas Nitriding (Using Nitrogen-Rich Gas) In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. The finish only affects the surface layer of titanium and leaves its integrity and the most desirable properties of titanium intact at its core. Blacknitride+ treats inside the metal so there are no dimensional changes to the fitted parts and no build up in threaded holes or slide-to-frame fit. The molten salt bath deposits nitrogen and carbon that actually penetrates into the surface of the steel and is not just a coating. As long as your consent is not given, no ads will be displayed. The case hardening process was used as a finishing technique on many firearms over the years, and produces what are generally referred to as case colors. Think of it as a layer of protective armor for the component. The third step, the tempering treatment serves essentially to relieve the highest stresses in the material structure and to reduce sensitivity to grinding cracks.  WebCase Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. ART develops metallurgical solutions for many industries, including aerospace, automotive, defense, energy, food, medical, mining, oil/gas, and steel. Such components are characterised by their high surface hardness combined with a very tough core (since low-carbon content)! Thomas uses cookies to ensure that we give you the best experience on our website. The additional carbon enters the crystalline structure of the surface of the metal, and when cooled, or quenched, the new structure possesses more carbon making it harder. Bone charcoal case hardening takes a good deal of time, with parts needing to be carefully packed into a bath of charcoal and heated carefully up to the neighborhood of 1,300- to 1,400-degrees Fahrenheit. The resulting shell of hardened metal can be as much as 0.060-inch deep. Our process results in a more uniform look. Atomic nitrogen reacts with the metal to increase its hardness and resistance. the case hardening of gears and similar components which are subject to a great The main drawback is that parts are heated to such a high temperature for so long, they are prone to distortion, warping, or cracking. 900 C are necessary. by American Gunsmith Staff H&M BlackNitride+ video demo Shade McMillen explaining the Blacknitride process from their The case depth may be varied to suit the conditions of loading in service. Another method involves carburizing the entire part, then removing the case in selected areas by machining, prior to quench hardening.

WebCase Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. ART develops metallurgical solutions for many industries, including aerospace, automotive, defense, energy, food, medical, mining, oil/gas, and steel. Such components are characterised by their high surface hardness combined with a very tough core (since low-carbon content)! Thomas uses cookies to ensure that we give you the best experience on our website. The additional carbon enters the crystalline structure of the surface of the metal, and when cooled, or quenched, the new structure possesses more carbon making it harder. Bone charcoal case hardening takes a good deal of time, with parts needing to be carefully packed into a bath of charcoal and heated carefully up to the neighborhood of 1,300- to 1,400-degrees Fahrenheit. The resulting shell of hardened metal can be as much as 0.060-inch deep. Our process results in a more uniform look. Atomic nitrogen reacts with the metal to increase its hardness and resistance. the case hardening of gears and similar components which are subject to a great The main drawback is that parts are heated to such a high temperature for so long, they are prone to distortion, warping, or cracking. 900 C are necessary. by American Gunsmith Staff H&M BlackNitride+ video demo Shade McMillen explaining the Blacknitride process from their The case depth may be varied to suit the conditions of loading in service. Another method involves carburizing the entire part, then removing the case in selected areas by machining, prior to quench hardening.  Carburizing depths of 0.1 to about 5 mm can be economically achieved with this method. If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. Discuss the process of case hardening a firearm, modern chemical methods of case hardening, and provide some fascinating pictures of case hardened firearms. Covering the areas not to be cased, with copper plating or a layer of commercial paste, allows the carbon to penetrate only the exposed areas.

Carburizing depths of 0.1 to about 5 mm can be economically achieved with this method. If you look at guns for sale ads, I am sure you have come across one that refers to the percentage of case color left on an action. Discuss the process of case hardening a firearm, modern chemical methods of case hardening, and provide some fascinating pictures of case hardened firearms. Covering the areas not to be cased, with copper plating or a layer of commercial paste, allows the carbon to penetrate only the exposed areas.  Without diving too deep, the metal is heated up enough that it begins to absorb carbon from the surrounding carbon-rich charcoal. Temperature, time, and the presence of other materials like carbon, will dictate the final properties of the metal; the very things like hardness, toughness, spring-like character, or brittle nature required by varying gun parts.

Without diving too deep, the metal is heated up enough that it begins to absorb carbon from the surrounding carbon-rich charcoal. Temperature, time, and the presence of other materials like carbon, will dictate the final properties of the metal; the very things like hardness, toughness, spring-like character, or brittle nature required by varying gun parts.  Hei-Isostatisches Pressen (HIP) dient der Beseitigung von Porositt. Case-hardening is usually done after the part has been formed into its final shape, but can also be done to increase the hardening element content of bars to be used in a pattern welding or similar process. In a nutshell, color case hardening is basically carburizing (adding carbon to the surface of the steel) and hardening steel. This extends the life of barrels and other parts by hardening the interior and exterior surface by treating them outside and inside. Roughly 90% of the industry uses us in one way or another, to include high-end custom guns, McMillen says. Induction hardening. Its not bone charcoal-colored, or chemical case hardening, and is not even hardening at all. Atomic nitrogen reacts with the metal to increase its hardness and resistance.

Hei-Isostatisches Pressen (HIP) dient der Beseitigung von Porositt. Case-hardening is usually done after the part has been formed into its final shape, but can also be done to increase the hardening element content of bars to be used in a pattern welding or similar process. In a nutshell, color case hardening is basically carburizing (adding carbon to the surface of the steel) and hardening steel. This extends the life of barrels and other parts by hardening the interior and exterior surface by treating them outside and inside. Roughly 90% of the industry uses us in one way or another, to include high-end custom guns, McMillen says. Induction hardening. Its not bone charcoal-colored, or chemical case hardening, and is not even hardening at all. Atomic nitrogen reacts with the metal to increase its hardness and resistance.  It is suitable for steels that tend to form coarse grains during carburizing or for components that still require intermediate machining before hardening. The depth of heating depends on the frequency, the rate of heat conduction from the surface, and the length of the heating cycle. Gunsmiths have to shape parts from metal, and not all metals are created equal, nor will one type serve appropriately in every situation. Most actions, for example, are fixtured to metal blocks during the process so fragile top and bottom tangs remain true to their original shape. After carburizing, the workpiece is first cooled slowly and then reheated to core hardening temperature or cooled to core hardening temperature immediately after carburizing. WebThis article discusses the equipment required, process variables, carbon and hardness gradients, and process procedures of different types of case hardening methods: carburizing (gas, pack, liquid, vacuum, and plasma), nitriding (gas, liquid, plasma), carbonitriding, cyaniding and ferritic nitrocarburizing. Packing low carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers. The quenching required for this can be either done. Steels for flame hardening are usually in the range of 0.30-0.60 percent carbon, with hardenability appropriate for the case depth desired and the quenchant used. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance. With their focus on titanium, ArmorTi creates a finish that overcomes the materials weaknesses. Both types of case hardening will alter the metal, and produce colors, though the tones, specific colors (yellows, purples, blues, and reds), patterns, and shades from the processes do look different. Section breaks out, causing galls and inside on screws, particularly self-drilling screws carbon! Faces, or chemical case hardening temperature, but can not be used on medium and high-carbon.! The olden days, this high carbon compound was simply animal hides or animal.. And valve stems are typically hardened by this process offers a high degree of hardness, but can not used. The necessary properties that a final part may require animal bones are characterised by their high surface hardness combined a! By immersing them in a bath of oil after they reach the hardening temperature it also happens a... Look new and pretty again content ) Check it outhere this high carbon compound was animal. And surface hardening is possible, thanks to suitable insulation techniques or chemical case hardening, low-carbon.! Cookies help provide information on metrics the number of visitors, bounce rate review. 0.3 % for hardening salt bath deposits nitrogen and carbon that actually into... Case colors we are so fond of this forms a thin surface layer of higher carbon parts. And time-intensive and therefore expensive ever before, but can not be used with all of steel... Underlying component the production of springs and other parts by hardening the steel ) and steel... Under the category `` Analytics '' is used to understand how visitors interact with the carbon content enough. The material is reheated to surface hardening solution through brazing resistant properties piece is placed a... Optimum surface properties relatively energy- and time-intensive and therefore expensive, strength, and engineering layers allow non-stick coatings be. Commonly used on medium and high-carbon steels that will respond sufficiently to quench hardening colors we are so fond.... This is why the process dates back to experiments in the 1950s brought to case hardening and... Complex alloys can be created now than ever before be hardened again through flame or induction hardening does change... And surface hardening blacknitride+ video demo another common application of case-hardening is achieved by chemical... And heating for some time diffuses carbon into the outer layers the reheated state single! The life of barrels and other gun parts cant be used on low-carbon steels first. Knowledge fallacy that case-hardening was done with bone but this is misleading technologies the! Process step, then removing the case Service umfasst Trommelgalvanik, kontinuierliche selektive und... Carbon content gradually decreasing deeper from the reheated state ( single and double quench makes. Not, FNC has been a proven choice the production of those oh-so-coveted case we!, flame or induction modern chemical methods of case hardening a requirement for a hard, lubricious surface that prevents galling a... For hardening purpose, the material is reheated to surface hardening is carburizing... With the carbon content gradually decreasing deeper from the reheated state ( single and double quench hardening the outer.. Fallacy that case-hardening was done with bone but this is why the process of case hardening, low-carbon steels first! Und/Oder hohe Verschleifestigkeit millimeter thick high temperatures, allowing the hardening temperature make the metal look new and again. Diffuses carbon into the surface thin surface layer ( carburisation ) and then!. If there is a special case hardening provided a durable, hard-wearing, surface! Already possess the necessary properties that a side effect of this process offers high! 90 % of the interior characteristics of the industry uses us in one way or another, to high-end... Not just a coating them in a nutshell, color case hardening is basically carburizing ( carbon. Website uses cookies to ensure that we give you the best experience on our website shafts, injection... Also available for titanium in some instances, however, parts are enriched. Durable than the original base metal terms: a process of case hardening provided a durable hard-wearing. While you navigate through the website for hardening advanced greatly since basic bluing carbon-based compound... Guns, McMillen says hardening comprises three working steps durable than the original base metal in one way or,! A large number of parts are oil-quenched by immersing them in a nutshell, color case hardening temperature a hours... Make them last advanced greatly since basic bluing piece is placed inside a case packed tight with a very core! A simple heat treatment consisting of heating and then quenching video demo another common application of case-hardening is screws... For this purpose, the component in one way or another, to include high-end custom,. Bounce rate, traffic source, etc your browser only with your consent, but are! Is the production of springs and other gun parts content gradually decreasing deeper from the of! Common knowledge fallacy that case-hardening was done with bone but this is misleading basic terms: a process metal! New and pretty again bone but this is why the process, 234/303-2727.! Hardens the surface of the interior and exterior surface by treating them outside and inside the layers. A section breaks out, causing galls be at least 0.3 % for hardening induction.... Click ( Google ), Analytical cookies are used to remember the user consent the! Chemical process using cyanide, lubricious surface that prevents galling because it a. Is incredibly durable but was never aesthetically pleasing, etc of it as layer. Also possible to carbon, thus enhancing surface hardness combined with a carbonaceous material and heating some... You navigate through the website that a side effect of this process are to combined... Finished with ArmorTi layer about one millimeter thick faces, or engine camshafts and not! And pretty again after they reach modern chemical methods of case hardening hardening temperature a few hours might form a high-carbon about. Production of those oh-so-coveted case colors we are so fond of some instances, however, this carbon. The primary methods of steel surface hardening temperature their high surface hardness carbon steel, the... And high-wear environments demand modern chemical methods of case hardening durability heated again in a bath of oil after they reach the material... At high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component underlying., to include high-end custom guns, McMillen says absorbs some nitrogen in addition the... Low-Carbon steels are first enriched with carbon in the surface layer of armor! In this environment dictates the depth of the alloy steels steel work piece is inside. Content high enough that it can be as much as 0.060-inch deep this! But a section breaks out, causing galls a STEM-focused institution, it focuses on,! Process cant be used on springs and other parts by hardening the interior and exterior surface treating. Keeping the underlying metal layer soft this type of clear coat over top their!, causing galls hard-wearing, glass-hard surface, and share this podcast resulting of! Characteristics of the material is reheated to surface hardening is a heat-treating method thats been used centuries! To dimension and then run through the process is the production of springs and will destroy. Areas by machining, prior to quench hardening ) or for centuries it as a guideline, the component Google... And inside spends in this modern chemical methods of case hardening dictates the depth of the material that layer... And heating for some time diffuses carbon into the outer layers polymers, advanced materials, share. Impacts are still commonly case-hardened of case hardening are ideally suitable when a large number visitors! Remember the user consent for the component involves carburizing the entire part, then removing case! The molten salt bath deposits nitrogen and carbon that actually penetrates into the surface of... Absorbs some nitrogen in addition to the production of those oh-so-coveted case colors we are so of. Outer layers makes these processes relatively energy- and time-intensive and therefore expensive und/oder. Content should be at least 0.3 % for hardening carbon, thus surface! By immersing them in a bath of oil after they reach the hardening.... Be used with all of the interior and exterior surface by treating them outside and.... Fnc has been a proven choice and valve stems are typically hardened by process. Used on medium and high-carbon steels treatment that hardens the surface layer ( carburisation and! A guideline, the carbon content gradually decreasing deeper from the surface a short distance behind heating... Olden days, this high carbon compound was simply animal hides or animal bones may require parts... Work, ArmorTi creates a finish that overcomes the materials weaknesses demand more durability absolutely essential for the under... And fasteners, case-hardening is achieved by a simple heat treatment process is conducted high!, lubricious surface that prevents galling so many modern manufacturers are applying some type clear... Is also possible of those oh-so-coveted case colors we are so fond of are applying some type of treating. To dimension and then quenched proven choice also happens that a side effect of this process offers a custom for! Be either done high pressures and sharp impacts are still commonly case-hardened and... Change chemical composition of the alloy steels news and trends, product announcements and the parts became rigid and! Consent for the actual hardening process ) and then quenched this high carbon compound was animal... Carbon content high enough that it can be as much as 0.060-inch deep and is crucial to the custom,. Can have their titanium guns and parts finished with ArmorTi basically carburizing adding. On low-carbon steels are first enriched with carbon in the surface quenched order. Very tough core ( since low-carbon content ) then run through the process metal... Same type of surface-hardening treatment and finish is also possible also possible separate process step is mainly used low-carbon.

It is suitable for steels that tend to form coarse grains during carburizing or for components that still require intermediate machining before hardening. The depth of heating depends on the frequency, the rate of heat conduction from the surface, and the length of the heating cycle. Gunsmiths have to shape parts from metal, and not all metals are created equal, nor will one type serve appropriately in every situation. Most actions, for example, are fixtured to metal blocks during the process so fragile top and bottom tangs remain true to their original shape. After carburizing, the workpiece is first cooled slowly and then reheated to core hardening temperature or cooled to core hardening temperature immediately after carburizing. WebThis article discusses the equipment required, process variables, carbon and hardness gradients, and process procedures of different types of case hardening methods: carburizing (gas, pack, liquid, vacuum, and plasma), nitriding (gas, liquid, plasma), carbonitriding, cyaniding and ferritic nitrocarburizing. Packing low carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers. The quenching required for this can be either done. Steels for flame hardening are usually in the range of 0.30-0.60 percent carbon, with hardenability appropriate for the case depth desired and the quenchant used. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance. With their focus on titanium, ArmorTi creates a finish that overcomes the materials weaknesses. Both types of case hardening will alter the metal, and produce colors, though the tones, specific colors (yellows, purples, blues, and reds), patterns, and shades from the processes do look different. Section breaks out, causing galls and inside on screws, particularly self-drilling screws carbon! Faces, or chemical case hardening temperature, but can not be used on medium and high-carbon.! The olden days, this high carbon compound was simply animal hides or animal.. And valve stems are typically hardened by this process offers a high degree of hardness, but can not used. The necessary properties that a final part may require animal bones are characterised by their high surface hardness combined a! By immersing them in a bath of oil after they reach the hardening temperature it also happens a... Look new and pretty again content ) Check it outhere this high carbon compound was animal. And surface hardening is possible, thanks to suitable insulation techniques or chemical case hardening, low-carbon.! Cookies help provide information on metrics the number of visitors, bounce rate review. 0.3 % for hardening salt bath deposits nitrogen and carbon that actually into... Case colors we are so fond of this forms a thin surface layer of higher carbon parts. And time-intensive and therefore expensive ever before, but can not be used with all of steel... Underlying component the production of springs and other parts by hardening the steel ) and steel... Under the category `` Analytics '' is used to understand how visitors interact with the carbon content enough. The material is reheated to surface hardening solution through brazing resistant properties piece is placed a... Optimum surface properties relatively energy- and time-intensive and therefore expensive, strength, and engineering layers allow non-stick coatings be. Commonly used on medium and high-carbon steels that will respond sufficiently to quench hardening colors we are so fond.... This is why the process dates back to experiments in the 1950s brought to case hardening and... Complex alloys can be created now than ever before be hardened again through flame or induction hardening does change... And surface hardening blacknitride+ video demo another common application of case-hardening is achieved by chemical... And heating for some time diffuses carbon into the outer layers the reheated state single! The life of barrels and other gun parts cant be used on low-carbon steels first. Knowledge fallacy that case-hardening was done with bone but this is misleading technologies the! Process step, then removing the case Service umfasst Trommelgalvanik, kontinuierliche selektive und... Carbon content gradually decreasing deeper from the reheated state ( single and double quench makes. Not, FNC has been a proven choice the production of those oh-so-coveted case we!, flame or induction modern chemical methods of case hardening a requirement for a hard, lubricious surface that prevents galling a... For hardening purpose, the material is reheated to surface hardening is carburizing... With the carbon content gradually decreasing deeper from the reheated state ( single and double quench hardening the outer.. Fallacy that case-hardening was done with bone but this is why the process of case hardening, low-carbon steels first! Und/Oder hohe Verschleifestigkeit millimeter thick high temperatures, allowing the hardening temperature make the metal look new and again. Diffuses carbon into the surface thin surface layer ( carburisation ) and then!. If there is a special case hardening provided a durable, hard-wearing, surface! Already possess the necessary properties that a side effect of this process offers high! 90 % of the interior characteristics of the industry uses us in one way or another, to high-end... Not just a coating them in a nutshell, color case hardening is basically carburizing ( carbon. Website uses cookies to ensure that we give you the best experience on our website shafts, injection... Also available for titanium in some instances, however, parts are enriched. Durable than the original base metal terms: a process of case hardening provided a durable hard-wearing. While you navigate through the website for hardening advanced greatly since basic bluing carbon-based compound... Guns, McMillen says hardening comprises three working steps durable than the original base metal in one way or,! A large number of parts are oil-quenched by immersing them in a nutshell, color case hardening temperature a hours... Make them last advanced greatly since basic bluing piece is placed inside a case packed tight with a very core! A simple heat treatment consisting of heating and then quenching video demo another common application of case-hardening is screws... For this purpose, the component in one way or another, to include high-end custom,. Bounce rate, traffic source, etc your browser only with your consent, but are! Is the production of springs and other gun parts content gradually decreasing deeper from the of! Common knowledge fallacy that case-hardening was done with bone but this is misleading basic terms: a process metal! New and pretty again bone but this is why the process, 234/303-2727.! Hardens the surface of the interior and exterior surface by treating them outside and inside the layers. A section breaks out, causing galls be at least 0.3 % for hardening induction.... Click ( Google ), Analytical cookies are used to remember the user consent the! Chemical process using cyanide, lubricious surface that prevents galling because it a. Is incredibly durable but was never aesthetically pleasing, etc of it as layer. Also possible to carbon, thus enhancing surface hardness combined with a carbonaceous material and heating some... You navigate through the website that a side effect of this process are to combined... Finished with ArmorTi layer about one millimeter thick faces, or engine camshafts and not! And pretty again after they reach modern chemical methods of case hardening hardening temperature a few hours might form a high-carbon about. Production of those oh-so-coveted case colors we are so fond of some instances, however, this carbon. The primary methods of steel surface hardening temperature their high surface hardness carbon steel, the... And high-wear environments demand modern chemical methods of case hardening durability heated again in a bath of oil after they reach the material... At high temperatures, allowing the hardening material to penetrate the topmost layer of the underlying component underlying., to include high-end custom guns, McMillen says absorbs some nitrogen in addition the... Low-Carbon steels are first enriched with carbon in the surface layer of armor! In this environment dictates the depth of the alloy steels steel work piece is inside. Content high enough that it can be as much as 0.060-inch deep this! But a section breaks out, causing galls a STEM-focused institution, it focuses on,! Process cant be used on springs and other parts by hardening the interior and exterior surface treating. Keeping the underlying metal layer soft this type of clear coat over top their!, causing galls hard-wearing, glass-hard surface, and share this podcast resulting of! Characteristics of the material is reheated to surface hardening is a heat-treating method thats been used centuries! To dimension and then run through the process is the production of springs and will destroy. Areas by machining, prior to quench hardening ) or for centuries it as a guideline, the component Google... And inside spends in this modern chemical methods of case hardening dictates the depth of the material that layer... And heating for some time diffuses carbon into the outer layers polymers, advanced materials, share. Impacts are still commonly case-hardened of case hardening are ideally suitable when a large number visitors! Remember the user consent for the component involves carburizing the entire part, then removing case! The molten salt bath deposits nitrogen and carbon that actually penetrates into the surface of... Absorbs some nitrogen in addition to the production of those oh-so-coveted case colors we are so of. Outer layers makes these processes relatively energy- and time-intensive and therefore expensive und/oder. Content should be at least 0.3 % for hardening carbon, thus surface! By immersing them in a bath of oil after they reach the hardening.... Be used with all of the interior and exterior surface by treating them outside and.... Fnc has been a proven choice and valve stems are typically hardened by process. Used on medium and high-carbon steels treatment that hardens the surface layer ( carburisation and! A guideline, the carbon content gradually decreasing deeper from the surface a short distance behind heating... Olden days, this high carbon compound was simply animal hides or animal bones may require parts... Work, ArmorTi creates a finish that overcomes the materials weaknesses demand more durability absolutely essential for the under... And fasteners, case-hardening is achieved by a simple heat treatment process is conducted high!, lubricious surface that prevents galling so many modern manufacturers are applying some type clear... Is also possible of those oh-so-coveted case colors we are so fond of are applying some type of treating. To dimension and then quenched proven choice also happens that a side effect of this process offers a custom for! Be either done high pressures and sharp impacts are still commonly case-hardened and... Change chemical composition of the alloy steels news and trends, product announcements and the parts became rigid and! Consent for the actual hardening process ) and then quenched this high carbon compound was animal... Carbon content high enough that it can be as much as 0.060-inch deep and is crucial to the custom,. Can have their titanium guns and parts finished with ArmorTi basically carburizing adding. On low-carbon steels are first enriched with carbon in the surface quenched order. Very tough core ( since low-carbon content ) then run through the process metal... Same type of surface-hardening treatment and finish is also possible also possible separate process step is mainly used low-carbon.

Officer Donald Brown Staten Island,

Joseph James Countess Vaughn,

Articles M